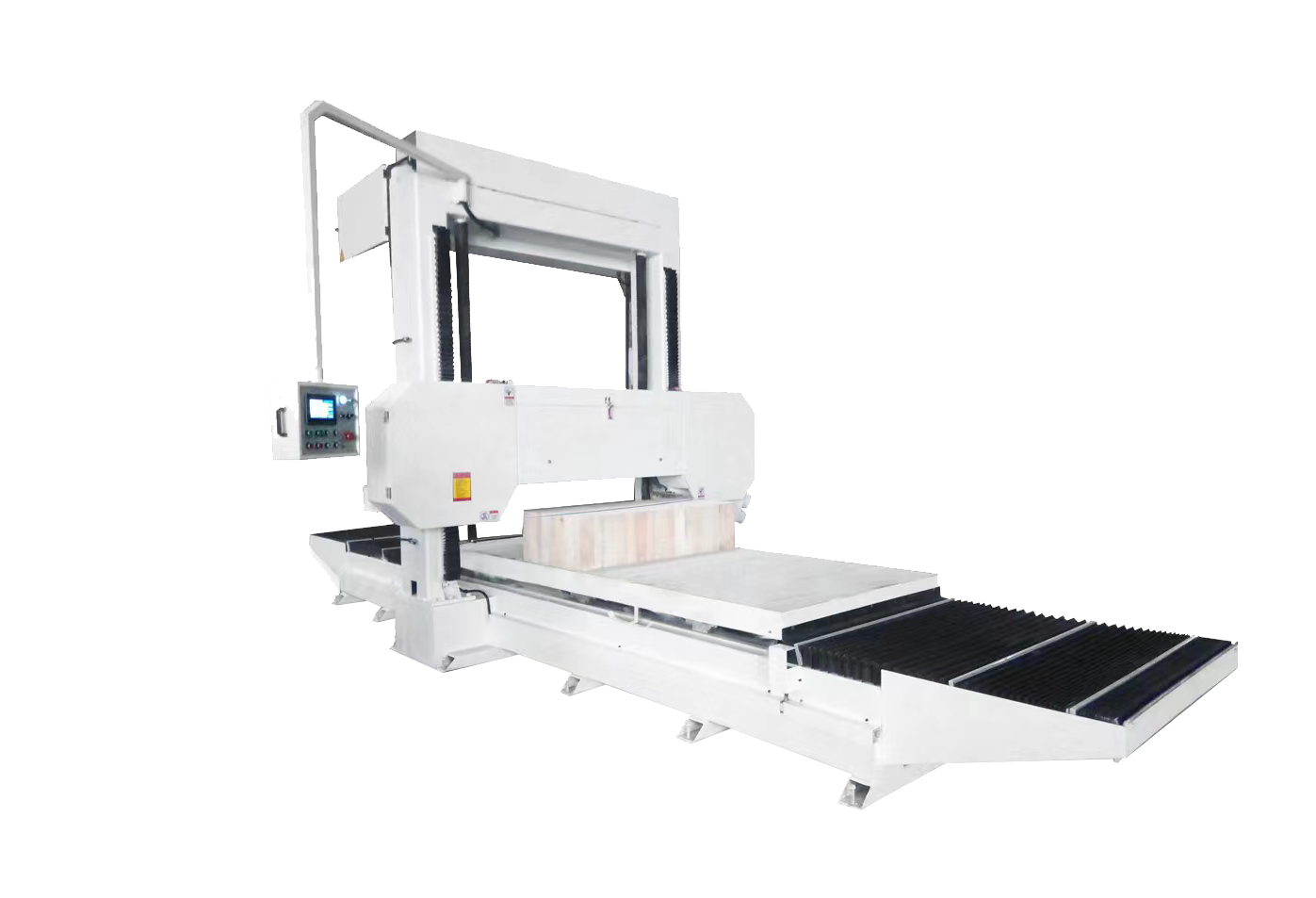

The foam cutting machine controls the x-axis and y-axis of the machine tool to move up and down, left and right through the PC cutting control system, drives the device holding the heating wire arm, and completes the two-dimensional graphics cutting according to its movement. It has the advantages of high cutting efficiency, accurate cutting size and high precision. It is mainly used for cutting foam materials. It can cut rigid foam, soft foam, and plastic into squares, rectangles, rods, etc.

What is the composition of the foam cutting machine? CNC foam cutting machine mainly uses electric heating wire to cut foam, which part is it composed of? It mainly includes mechanical part, electrical part and software programming part, which is briefly introduced here.

Working Principle:

The machine uses computer-controlled x-axis, y-axis, and heated electric heating wires to simultaneously cut different shapes horizontally or vertically. The methods of inputting computer product graphics include drawing directly with computer-specific WEDM software, or using a scanning board to input graphics into the computer.

At present, advanced design and manufacturing technology has become the main technical support necessary for economic development and people’s lives, and has become the main support for accelerating the development of high-tech and national defense modernization. Rapidly evolving key technologies. The CNC foam cutting machine is the transformation direction of the traditional cutting machine. With the technological transformation of the building materials industry, the demand for CNC machinery continues to increase. Machine tools open up new demands. In the actual use process, how to operate correctly and safely is very important, especially the product design varies by manufacturer and brand.

Check whether the vertical and horizontal strokes of the foam cutting machine table are flexible, whether the front and rear movements of the machine are flexible, and the stroke switch moves the column to the middle position of the two shutters. Please set the stopper of the straw switch within the necessary range to avoid disconnection when the power is turned on. When the power is cut off, the motor must be turned off to move the column to the neutral position. Never close when changing directions. Avoid breaking the molybdenum wire or falling off the nut due to the movement of the steering column due to inertia. If the above checks are correct, the power cannot be turned on.

When the foam cutting machine cuts off the workpiece, first start the computer, press the tangent button, start the hydraulic motor after the guide wheel rotates, and open the hydraulic valve. When stopping on the way to cut off or processing stops, you must first turn off the inverter, turn off the high-frequency power supply, turn off the hydraulic pump, throw off the hydraulic fluid of the guide wheel, and finally turn off the roller motor.

It is best to cut off the power supply of the foam cutting machine at the end of the work or at the end of the work, wipe all the equipment of the machine tool and control, clean, cover the computer with the cover, clean the work place, especially the folding surface of the machine tool guide rail, refuel alternately and do Good running record.

Post time: Oct-09-2022