According to the molding method, Polyurethane elastomers are divided into TPU, CPU and MPU.

CPU are further divided into TDI(MOCA) and MDI.

Polyurethane elastomers are widely used in machinery industry, automobile manufacturing, petroleum industry, mining industry, electrical and instrumentation industry, leather and shoe industry, construction industry, medical and health and sports goods manufacturing and other fields.

1. Mining:

(1) Mining sieve plate and screen: Screening equipment is the main equipment in mining, metallurgy, coal, building materials and other industries. Its key component is the sieve plate. The CPU sieve plate is used to replace the traditional steel sieve plate, and the weight can be greatly increased. Reduced energy consumption, easy to mold mesh with reasonable cross-sectional structure and elasticity. And reduce noise, the service life is also greatly improved. In addition, it is not easy to block the sieve, and it is not easy to stick to the sieve, because polyurethane is a macro-molecular substance, and the molecular binding polarity is small, and it does not adhere to wet objects, resulting in accumulation.

(2) Lining of mineral processing equipment: There are many mineral processing equipment for mining, which are most easily worn. After CPY lining is used, the service life can be increased by 3 to 10 times, and the total cost is greatly reduced.

(3) Ball mill lining: CPU is used as a simple lining, which not only saves steel, reduces weight, but also saves power and energy consumption, and the service life can be increased by 2 to 5 times.

(4) For the hoist friction lining block, replacing the engineering with CPU with high friction coefficient and high wear resistance can greatly improve the hoisting capacity and service life.

2. Mechanical industry:

(1) Cots:

①Metallurgical cots: CPU cots are currently mainly used in occasions with harsh working environment and high quality requirements, such as pinch rollers, tension rollers, pressure rollers, transfer rollers, guide rollers, etc.

②Printing rubber roller: It is divided into printing rubber roller, offset printing rubber roller and high-speed printing rubber roller, etc. Due to the low CPU hardness, high strength, elasticity, wear resistance, ink resistance and other properties, it is very suitable for low-hardness high-speed printing rubber rollers.

③Paper-making rubber roller: used as extrusion rubber roller and pulp rolling rubber roller, its production efficiency can be increased by more than 1 times, and energy consumption and cost can be reduced.

④ Textile rubber roller: used as pelletizing roller, wire drawing roller, drawing roller, etc., which can prolong the service life.

⑤ Various industrial rubber rollers such as mechanical equipment polyurethane rubber rollers.

(2)Belt: There are more than 300 kinds of commonly used polyurethane belts: large-scale conveyor belts and hoist belts such as mines and wharfs; medium-sized conveyor belts such as beer and various glass bottles; small-scale synchronous toothed belts, infinitely variable speed Belts, high-speed transmission belts, V-belts and V-ribbed belts, tiny precision instrument belts, timing belt,etc.

(3)Seals: mainly used as oil seals, especially high-pressure oil seals, such as hydraulic seals for construction machinery, forging press seals, etc. For example, the leather cup of the aircraft’s main landing gear is made of polyurethane elastomer, which increases its life by dozens of times and ensures flight safety. It has also achieved good results as a seal for liquid hydrogen.

(4) Elastic coupling element: long service life and good cushioning performance.

(5) Polyurethane grinding machine lining (medical equipment, electronics, glasses, hardware tools, medicine, ceramics, electroplating industries)

(6) Polyurethane miscellaneous parts, etc. (coupling hexagonal pads, cyclones, construction machinery rubber blocks, silk screen scrapers, shock pads for molds, sling series, corrugating machine pullers).

3. In the automotive suspension system industry:

Mainly used for wear parts, shock absorption parts, decoration, shock absorbers, sealing rings, jounce bumper, bushings, bump stop, elastic couplings, bumpers, leather, seals, decorative panels, etc.

4. Construction industry:

(1) Paving materials: indoor and sports ground paving.

(2) Ceramic and gypsum decorative molds have gradually replaced traditional steel molds.

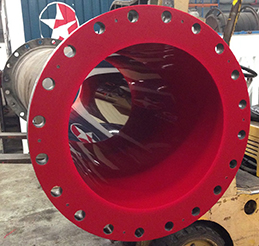

5. Petroleum industry:

The oil exploitation environment is harsh, and the sand and gravel are seriously worn, such as mud pump oil plug, Vail rubber, cyclone, hydraulic seal, casing, bearing, hydrocyclone, buoy, scraper, fender , valve seat, etc. are made of polyurethane elastomer.

6. Other aspects:

(1) Aircraft: interlayer film, coating

(2) Military: tank tracks, gun barrels, bulletproof glass, submarines

(3) Sports: sports courts, running tracks, bowling, weight-lifting equipment, dumbbells, motorboats, skateboard wheels(In 2016, the International Olympic Committee declared skateboarding an official Olympic sport),etc.

(4) Coatings: exterior and interior wall coatings, diving coatings, construction, color steel plates, etc., furniture coatings

(5) Adhesive: agent: high-speed rail, tape, mine cold repair glue, cable, highway seam glue

(6) Railway: sleepers, anti-vibration blocks.

(7) Elastomers have also been widely used in daily life, such as luggage universal wheels, roller skate wheels, elevator guide rollers, elevator buffers, etc.

Post time: May-06-2022