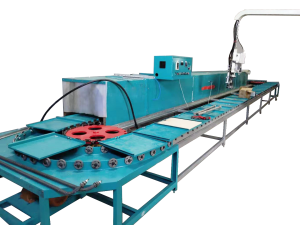

Polyurethane PU Foam Outdoor Floor Mat Injection Production Line For Prayer Rug Making

Fully automatic multi-color floor mat production line is used to produce various polyurethane foam floor mats, including floor mats, car floor mats, etc.

The whole circular production line consists as following

1、The drive system: the driving device of the circular line.

2、Rack and slide.

3、Ground rail.

4、14 groups of trolleys: each group of trolley can put a pair of molds.

5、Power supply system.

6、The gas supply system: production line with 2 sets of 25L pump gas source pipeline, gas tank, pressure monitoring.

7、Mold temperature control system: 2 water tanks; 2 mold temperature machine, a mold temperature for 7 groups of trolley.

8、Security Defending system.

9、Electrical control system.

10、Automatic identification system.

The whole polyurethane floor mat production line consists of a circular production line, a mold base, a floor mat mold, and a low-pressure foaming machine.

The fourteen station foaming line is arranged in a planar ring structure, and the frequency conversion motor is used to drive the whole motion of the wire body through a variable speed turbine box. The speed of the transmission line can be adjusted by frequency conversion, which is convenient to adjust the production rhythm.

Technical Parameter of low pressure foam machine

|

No.

|

Item

|

Technical Parameter

|

|

1

|

Foam application

|

Flexible foam

|

|

2

|

Raw material viscosity(22℃)

|

POL ~3000CPS

ISO ~1000MPas |

|

3

|

Injection Output

|

155.8-623.3g/s

|

|

4

|

Mixing ratio range

|

100:28~50

|

|

5

|

Mixing head

|

2800-5000rpm, forced dynamic mixing

|

|

6

|

Tank Volume

|

120L

|

|

7

|

Metering pump

|

A pump: GPA3-63 Type B Pump: GPA3-25 Type

|

|

8

|

Compressed air requirement

|

Dry, oil free P:0.6-0.8MPa

Q:600NL/min(Customer-owned) |

|

9

|

Nitrogen requirement

|

P:0.05MPa

Q:600NL/min(Customer-owned) |

|

10

|

Temperature control system

|

heat:2×3.2kW

|

|

11

|

Input power

|

three-phrase five-wire,415V 50HZ

|

|

12

|

Rated power

|

about 13KW

|

Anti-slip and anti-fatigue mats, high-performance anti-fatigue, relieve the pressure of blood circulation on the feet, and improve the health index and safety factor of employees. Resistant to acid and alkali solvents. It is convenient to clean, easy to move, and does not affect the normal working environment.