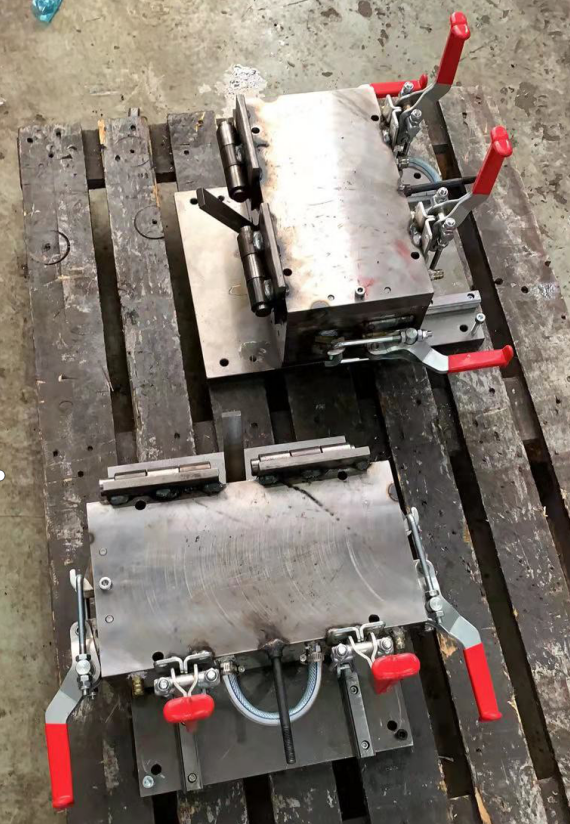

PU Trowel Mold

Polyurethane Plastering Float differs itself from old products, by overcoming the shortcomings such as heavy, inconvenient to carry and use, easy worn and easy corrosion, etc. The greatest strengths of Polyurethane Plastering Float are light weight, strong strength, abrasion resistance, corrosion resistance, anti-moth, and low temperature resistance, etc. With higher performance than polyester, glass fiber reinforced plastic and plastics, Polyurethane Plastering Float is a good substitution of similar products made of wood or iron.

Features

1. Light weight: good resilience and tenacity, light and hard,.

2. Fire-proof: reach the standard of no combustion.

3. Water-proof: no moisture absorbing, water permeation and mildew arising.

4. Anti-erosion: resist acid and alkali

5. Environment protection: using polyester as raw material to avoid lumbering

6. Easy to clean

7. OEM service: We have employed R&D center for research, advanced production line, professional engineers and workers,service for you.Also we have successfully developed a design partnership with our OEM clients. Because of the unique high load capacity, high elasticity, wear and tear resistance of our casters and wheels, we are widely chosen by many customers in Middle East, European, South Asia, South America, etc.

We can make mold for any size trowel like normal size 14*28, 18*32 and 20*36 and any shape trowels are also available.