From Waste to Raw Material: The Value and Trends of PU Recycling

We are a polyurethane equipment manufacturer with 30 years of experience in the polyurethane industry. Our equipment is widely used in various sectors. However, we are also concerned about the disposal of scrap materials and finished product waste during production, which has attracted the attention of many customers.

Can polyurethane be recycled?

Polyurethane can be recycled, generally through three methods: physical, chemical, and energy-based. Physical methods regenerate polyurethane through crushing and recompacting ; chemical methods decompose polyurethane to recover raw materials; and energy-based methods recover heat energy through incineration .

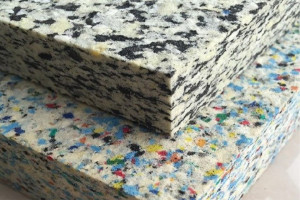

Physical recycling method : crush waste polyurethane into granules or powder, then compact it with glue , or use it as a filler.

- Advantages: Simple technology, low cost.

- Disadvantages: The recycled products have poor performance and limited applicability.

Chemical recycling : The process involves degrading the material through chemical reactions to produce new polyurethane products.

| Recycling methods | Process Description | Scope of application | Features |

| alcoholysis | using polyols to obtain recycled polyols. | hard foam, soft foam | High-quality recycled materials can be re-foamed. |

| pyrolysis | High-temperature decomposition of polyurethane produces oil, gas, and carbon slag. | Waste PU products | High investment, but can achieve deep resource utilization. |

| Blending method | Production of recycled and virgin materials | Various PU products | Controllable performance and wide application |

- Advantages: High quality , high recycling value, and good performance of recycled polyurethane.

- Disadvantages: The technology is complex and requires pre-sorting; otherwise, the generated products will still be waste .

Energy recovery method : Direct incineration to recover the heat energy generated.

- Advantages: It can process waste.

- Disadvantages: It may cause secondary pollution, so it is rarely used nowadays.

What are the advantages and disadvantages of recycled polyurethane?

Advantages of recycled polyurethane

- Reduce raw material costs

- The cost is only 50% to 70% of that of virgin materials.

- In the mid-range fields of flexible foam, rigid foam, sound insulation materials, floor mats, and packaging foam, the performance fully meets the requirements.

- It is especially suitable for use in foam product factories, shoe insole factories, and insulation board factories.

- Reduce waste and improve utilization.

- Waste, scraps, and rework materials generated during the production process can all be reused.

- Waste materials are recycled on-site and reused on the same day.

- Strong equipment compatibility

- mixed with virgin material for use.

- The recycled polyols obtained from chemical recovery can be compatible with standard formulations in proportion.

- No large-scale modifications to the production line are required; only the recycling and metering processes need to be added.

- Quick return on investment

- Taking a medium-sized foam factory as an example, it produces about 300 tons of waste material per year. If a recycling system is used, it can save about 800,000 to 1.2 million yuan in raw material costs every year.

- The payback period for a recycling system is typically 8 to 12 months.

Disadvantages of recycled polyurethane

- Recycled polyurethane has slightly lower resilience.

- Impurities cause color differences and affect the appearance.

- Moisture content, particle size, and ratio must be precisely controlled, otherwise the foaming stability will be affected.

- Not suitable for high-performance products such as car interiors, memory foam pillows, and high-elasticity shoe soles.

What are the applications of recycled polyurethane?

Polyurethane waste recycling generally falls into two main categories: physical recycling and chemical recycling . The two methods have different application areas:

Physical Recycling Applications

Sound and heat insulation materials:Rigid foam powder mixed with adhesives can be made into sound insulation boards and wall filling materials. The finished products have good thermal insulation properties and adjustable flame retardancy, and are widely used in the construction industry .

Sports mats, floor mats, yoga mats:Made by mixing and pressing recycled soft foam with glue, they have good elasticity and softness. They are commonly used in the sporting goods and fitness equipment industries.

Chemical Recycling Applications

Typical Application Classification Table

| Application areas | Regeneration form | process | Features |

| Carpet mats, sports mats | Recycled foam | Mechanical pressing | Low cost and good sound absorption |

| Packaging materials | Regenerated Particles | Crushing and pressing | Shockproof and dropproof |

| Building insulation layer | Regenerated rigid foam | Crushing, filling, or re-foaming | Insulation and fireproof |

| Furniture cushions | Recycled foam blending | Blending and foaming | Moderate elasticity, saving raw materials |

| Regenerated polyols | Liquid raw materials | alcoholysis, ammonolysis | It can be used to re-prepare PU foam |

| Paints and adhesives | Modified polyether | Alcohololysis and Resynthesis | Good adhesion |

| Energy fuel | pyrolysis oil, syngas | Thermal pyrolysis | Reuse of highly polluting materials |

Comprehensive recommendations for manufacturers

| Application directions | Recommended Regeneration Method | Virgin material replacement ratio | Remark |

| Insulation panels, cold storage panels | alcoholysis | 20–40% | Rigid foam systems have good compatibility |

| Floor mats, sound insulation materials | Physical recycling method | 50–100% | Low cost preferred |

| Packaging foam | Blending method | 30–60% | Low appearance requirements |

| Insoles, sports flooring | Blending method + auxiliaries | 10–30% | Performance controllable |

| Sales of recycled polyols | alcoholysis | – | Available for external supply |

Development Prospects of Recycled Polyurethane

Key Market Prospect Areas

- Building Energy Efficiency and Insulation Materials : Recycled rigid polyurethane foam can be used in insulation boards, spray coatings, cold storage panels, etc. The average annual growth rate is projected to reach 8-10% over the next 5 years.

- Furniture and Soft Foam Industry

Waste sofa cushions and mattress foam can be recycled to produce floor mats and filling foam. In Europe and Japan, recycling rates have exceeded 30%.

- Automotive and Transportation Sector

Polyurethane (PU) materials are widely used in automotive seat foam, sound insulation cotton, and other applications. Recycled foam or recycled polyols can be used in non-structural components such as interior trim and carpet padding.

- Footwear materials and sporting goods

Recycled polyurethane powder is blended with virgin materials to make shoe soles and insoles, which is low-cost and in line with the trend of environmental protection (brands such as Adidas and Nike have begun to use recycled PU materials).

Economic and Investment Prospects

| index | Current stage | Future Trends |

| Raw material cost savings | 20–40% | Continuous stability |

| Construction cost of recycling system | Medium (1 million–3 million RMB) | The investment payback period is approximately 8–12 months. |

| Market acceptance | Medium to low | Rapid growth (especially in the European and American markets) |

| Policy support | Increasingly | It is expected to be included in the renewable resources subsidy system. |

For polyurethane manufacturers, choosing recycled polyurethane is not only an environmentally friendly option, but also a new source of profit growth.

Summarize

Through various recycling methods, including physical and chemical processes, waste polyurethane can be applied to multiple fields such as floor mats, insulation boards, shoe insoles, and coatings, maximizing resource recycling. Recycled polyurethane not only reduces production costs and waste emissions but also holds the potential to become a new profit growth point for polyurethane manufacturers.

Post time: Nov-10-2025