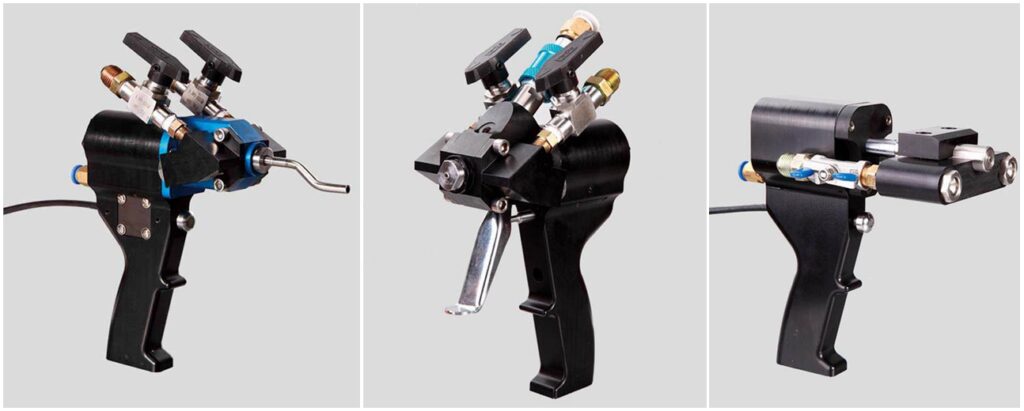

PolyurethaneSpray Gun Trigger Stuck?

In polyurethane spraying operations, the sensitivity of the spray gun directly affects the construction efficiency and foaming quality. Some users reported that the spray gun trigger was stuck and could not rebound smoothly, which not only affected the normal operation, but also caused equipment damage or uneven spraying in serious cases. So, what are the reasons for the spray gun trigger getting stuck? How to troubleshoot and deal with it?

1. Common reasons why the spray gun trigger of the pu sprayer is stuck

PolyurethaneSpray Gun Trigger Stuck?

After long-term use, impurities such as dust and residual paint may clog the internal gap of the trigger switch, causing the sliding of the parts to be blocked and affecting the rebound.

The O-ring of the spray gun is aging or worn

If the O-ring used in the trigger assembly is exposed to heat or friction for a long time, it is easy to deform and lose its elasticity, causing sealing failure, thereby hindering normal operation.

The spring force of the spray gun is insufficient

The rebound of the spray gun trigger relies on the internal spring to provide power. If the spring is aged and the elastic force is weakened, it will not be able to reset in time after pressing.

Air source problem of spray gun ( blockage/insufficient air pressure)

If the air path of the spray gun is blocked or the air source pressure is unstable, it may also cause the pneumatic trigger to move improperly and indirectly cause jamming.

2. Corresponding solution suggestions

Clean the internal structure of the spray gun trigger

Use a special cleaning agent to clean the oil and residual paint inside the trigger switch. Regular maintenance will help avoid recurring jamming problems.

Replace worn O-rings

Once the seal is found to be aging or deformed, it should be immediately replaced with the original O-ring to ensure the sealing and rebound effects.

Check the status of the spray gun spring assembly

If the spring force is insufficient or broken, replace the spring or the entire trigger assembly in time to restore normal mechanical feedback.

Check the air supply pressure

Check whether the air pipe is blocked, whether the filter is dirty and blocked, and whether the air compressor supply is stable to ensure smooth operation of the spray gun system.

Tips: To avoid damage to the spray gun structure due to self-disassembly, it is recommended to have professional technicians inspect and repair it.

Professional equipment requires professional maintenance

Although the spray gun is small, it is one of the most critical components in the spraying equipment. Regular inspection, correct use and timely maintenance are the key to ensure the long-term stable operation of the equipment. If you encounter any problems during use, please contact our after-sales technical team, we will provide you with a fast and efficient solution.

Post time: Jul-17-2025