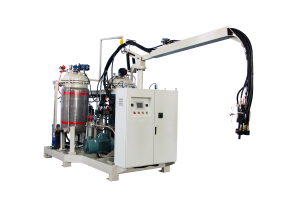

Polyurethane high-pressure foaming machine refers to the special equipment for polyurethane foam infusion and foaming. Polyurethane in-situ foaming can quickly pack, buffer and fill space for large finished products in a very short time, ensuring that products are transported and stored in storage. And the process of loading and unloading to obtain safety protection, suitable for the protective packaging of various products of the opposite sex, high added value, fragile, export and other products.

The raw materials of polyurethane components are accurately proportioned and stirred at high speed through this equipment according to certain requirements. Stir vigorously to make the material liquid evenly sprayed out, forming the required uniform, qualified and economical packaging material, fast, on-site foam packaging, this packaging method breaks the previous packaging mode, saves space, provides Packaging efficiency, packaging effect and beautifying the image of product packaging. Polyurethane high pressure foaming machine This kind of material can realize its function by direct operation of Comvit polyurethane foaming machine equipment, simple operation, beautiful masterpiece. The polyurethane high-pressure foaming machine has more prominent advantages for some export products. The rapid on-site foaming packaging does not contain CFC or HCFC and other components that destroy the ozone layer, which meets the international requirements for environmental protection.

In the composition of the system structure, the polyurethane foaming machine can be classified into: high-speed impeller type, high-pressure air type, and medium and low pressure blast type. A complete polyurethane foaming machine consists of the following systems: material flow system, metering system, air system, heating system, cleaning system, and mixing device.

Post time: Oct-19-2022