Ho latela mokhoa oa ho bopa, li-elastomer tsa Polyurethane li arotsoe ka TPU, CPU le MPU.

CPU e boetse e arotsoe ka TDI(MOCA) le MDI.

Li-elastomer tsa polyurethane li sebelisoa haholo indastering ea mechini, tlhahiso ea likoloi, indasteri ea peterole, indasteri ea meepo, indasteri ea motlakase le lisebelisoa, indasteri ea letlalo le lieta, indasteri ea kaho, tlhahiso ea thepa ea bongaka le bophelo bo botle le lipapali le likarolo tse ling.

1. Morafo:

(1)Letlapa la sieve la merafoleskrineng: Lisebelisoa tsa ho hlahloba ke lisebelisoa tse ka sehloohong tsa merafo, metallurgy, mashala, thepa ea mohaho le liindasteri tse ling.Karolo ea eona ea bohlokoa ke poleiti ea sieve.Letlapa la sieve la CPU le sebelisoa ho nkela poleiti e tloaelehileng ea sieve, 'me boima bo ka eketsoa haholo.Ho fokotsa tšebeliso ea matla, ho bonolo ho bopa mesh e nang le sebopeho se nang le likarolo tse fapaneng le elasticity.Le ho fokotsa lerata, bophelo ba ts'ebeletso le bona bo ntlafalitsoe haholo.Ho phaella moo, ha ho bonolo ho thibela sieve, 'me ha ho bonolo ho khomarela sieve, hobane polyurethane ke ntho e kholo ea limolek'hule,' me polarity e tlamang limolek'hule e nyenyane, 'me ha e khomarele lintho tse metsi, e leng se etsang hore ho be bonolo ho thibela sieve. ka ho bokellana.

(2) Lesela la lisebelisoa tsa ho lokisa liminerale: Ho na le lisebelisoa tse ngata tsa ho lokisa liminerale bakeng sa merafo, tse aparoang habonolo.Ka mor'a hore ho sebelisoe lesela la CPY, bophelo ba tšebeletso bo ka eketsoa ka makhetlo a 3 ho isa ho a 10, 'me litšenyehelo tsohle li fokotsehile haholo.

(3) Ball mill line: CPU e sebelisoa e le lesela le bonolo, le sa bolokeng tšepe feela, le fokotsa boima ba 'mele, empa hape le boloka matla le tšebeliso ea matla,' me bophelo ba tšebeletso bo ka eketsoa ka makhetlo a 2 ho isa ho a 5.

(4) Bakeng sa lesela la khokahanyo ea hoist, ho nkela boenjiniere sebaka ka CPU ka coefficient e phahameng ea likhohlano le ho hanyetsa ho hoholo ho ka ntlafatsa haholo bokhoni ba ho phahamisa le bophelo ba ts'ebeletso.

2. Indasteri ea mechini:

(1)Libethe:

① Libethe tsa tšepe:Libethe tsa CPUhajoale li sebelisoa haholo linakong tse nang le tikoloho e thata ea ho sebetsa le litlhoko tsa boleng bo holimo, joalo ka lirolara, lirolara tsa tsitsipano, lirolara tsa khatello, lirolara tsa phetisetso, lirolara tse tataisang, jj.

②Ho hatisarolara rabara: E arotsoe ka khatiso ea rabara ea rabara, rabara ea khatiso ea rabara ea rabara le rolara ea rabara ea khatiso e phahameng ka potlako, joalo-joalo -thata lirolara tsa rabara tse hatisang ka lebelo le phahameng.

③Pampiri-ho etsa rolara ea rabara: e sebelisoang e le rabara ea rabara ea extrusion le pulp rolling rabara, katleho ea eona ea tlhahiso e ka eketsoa ka makhetlo a fetang 1, mme tšebeliso ea matla le litšenyehelo li ka fokotsoa.

④ Textile rabara rolara: e sebelisoa e le rolara ea pelletizing, roller ea ho taka terata, roller ea ho taka, joalo-joalo, e ka lelefatsang bophelo ba ts'ebeletso.

⑤ Lirolara tse fapaneng tsa rabara tsa indasteri joalo ka lisebelisoa tsa mochini tsa polyurethane rabara.

(2)Lebanta:Ho na le mefuta e fetang 300 ea mefuta e sebelisoang hangatamabanta a polyurethane: boholomabanta a tsamaisang thepalehoist mabantajoalo ka merafo le boema-kepe;mabanta a conveyor a boholo bo mahareng a kang biri le libotlolo tse fapaneng tsa khalase;mabanta a menoana a manyenyane, Mabanta a lebelo a sa fetoheng, mabanta a phetiso a lebelo le phahameng, mabanta a V le likhopo tsa V, mabanta a lisebelisoa tse nepahetseng hantle,lebanta la nako, joalo-joalo.

(3) Litiiso: haholo-holo li sebelisoa e le litiiso tsa oli, haholo-holo likhatello tse phahameng tsa oli, tse kang litiiso tsa hydraulic bakeng sa mechine ea kaho, litiiso tsa khatiso, joalo-joalo. e eketsang bophelo ba yona ka makgetlo a mangata le ho netefatsa polokeho ya sefofane.E boetse e fihletse litholoana tse ntle joalo ka tiiso bakeng sa hydrogen e metsi.

(4) Elastic coupling element: bophelo bo bolelele ba ts'ebeletso le ts'ebetso e ntle ea cushioning.

(5) Lesela la mochini o silang oa polyurethane (lisebelisoa tsa bongaka, lisebelisoa tsa elektroniki, likhalase, lisebelisoa tsa Hardware, meriana, lirafshoa, liindasteri tsa electroplating)

6

3. Ka har'atsamaiso ea ho emisa likoloiindasteri:

Haholo-holo e sebelisoa bakeng sa likarolo tsa ho roala, likarolo tsa ho monya, mokhabiso,lintho tse nyarosang, masale a ho tiisa, qhoma bumper.

4. Indasteri ea kaho:

(1) Lisebelisoa tsa ho betla: ho betla fatše ka tlung le lipapaling.

(2) Mefuta e khabisitsoeng ea ceramic le gypsum butle-butle e nkile sebaka sa mefuta ea tšepe ea setso.

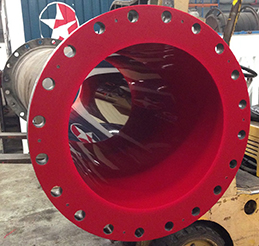

5. Indasteri ea peterole:

Tikoloho ea tšebeliso ea oli e thata, 'me lehlabathe le lehlohlojane li koaletsoe haholo, joalo ka plug ea oli ea pompo ea seretse, rabara ea Vail, leholiotsoana, hydraulic seal,khase, ho beha, hydrocyclone, buoy,scraper, fender , setulo sa valve, joalo-joalo li entsoe ka polyurethane elastomer.

6. Likarolo tse ling:

(1) Lifofane: filimi ea interlayer, ho roala

(2) Sesole: lipilara tsa litanka, libarele tsa lithunya, likhalase tse thibelang likulo, likepe tse tsamaeang ka tlas’a metsi

(3)Lipapali:mabala a lipapali, lipina tsa mabelo, bowling, thepa ea ho phahamisa litšepe,li-dumbbells, liketsoana tsa enjene,mabili a skateboard(Ka 2016, Komiti ea Machaba ea Liolimpiki e phatlalalitse skateboarding e le papali ea molao ea Liolimpiki), joalo-joalo.

(4) Liaparo tsa ka ntle le tse ka hare tsa lebota, liphahlo tsa ho qoela, kaho, lipoleiti tsa tšepe tsa mebala, joalo-joalo, liphahlo tsa thepa ea ka tlung.

(5) Sekhomaretsi: sekhomaretsi: seporo sa lebelo le holimo, teipi, sekhomaretsi sa ho lokisa serame sa morafo, thapo, sekhomaretsi sa tsela e kholo.

(6) Terene: batho ba robalang, litene tse thibelang ho thothomela.

(7) Lielastomer le tsona li ’nile tsa sebelisoa haholo bophelong ba letsatsi le letsatsi, joalokathōtō mabili a bokahohle,mabili a roller skate, lirolara tse tataisang lifti, lisebelisoa tsa lifti, joalo-joalo.

Nako ea poso: May-06-2022