Open Cell Foam Planer Wall Grinding Machine Foam Cutting Tool Insulation Trimming Equipment 220V

Describtion

The wall after urethane spray is not clean, this tool can make the wall clean and tidy. Cut corners quickly and easily. It also uses a swivel head to feed into the wall by driving the head directly onto the stud. When used properly, this can reduce the amount of work required to operate the clipper.

Operation way:

1. Use your both hands and firmly grips boths handles of the power and the cutter head.

2. start by completely trimmings the bottom two feet of the wall so you can avoid running the cutter bar through a pile of trimmings,and possibly cutting a hidden power cordmor hitting other obstacles.

3. do not runn the cutter over the edges of the steel hangers or braces.

as the power and speed needed to cut foam quicly may cause the ridged edges ot tear off the cutter teeth.

4. To use the cutter eaiser and clener,run it up the wall with the cutter turnung and taking a light cut.

5.Use the small ,drill powered cutter to trim around receptacles,hangers and other tight places.

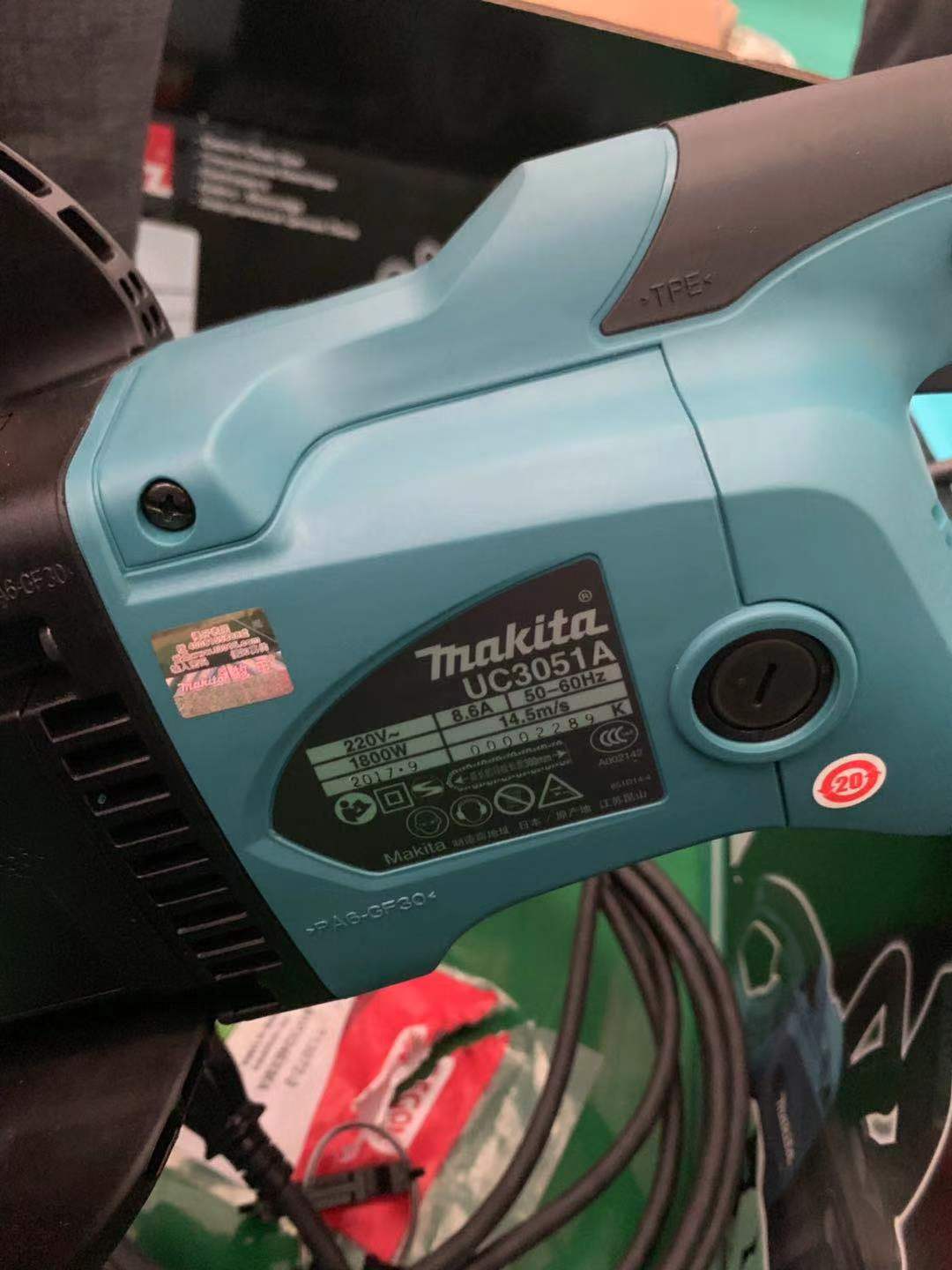

| Rated power | 1800 |

| Scope of application | Polyurethane thermal insulation and sound insulation foam planing |

| Tool shaft speed | 14.5 |

| Planing width | 500 |

| Grooving depth | 0 |

| Power cord length | 5 |

| Planing depth | 0 |

| Appendix | manual |

| Battery power | 0 |

| Rated voltage range | AC single-phase and DC 50V and below |

| Transfer method | Direct drive |

| Voltage | 220 |

| Weight | 12 |

| Power Type | AC power |

| Rated torque | 0 |

| No-load speed | 14.5 |