Pneumatic Polyurethane Spray Foam Machine Polyurethane Fome Insulation Spray Machine

- One-button operation and digital display counting system, easy to master the operation method

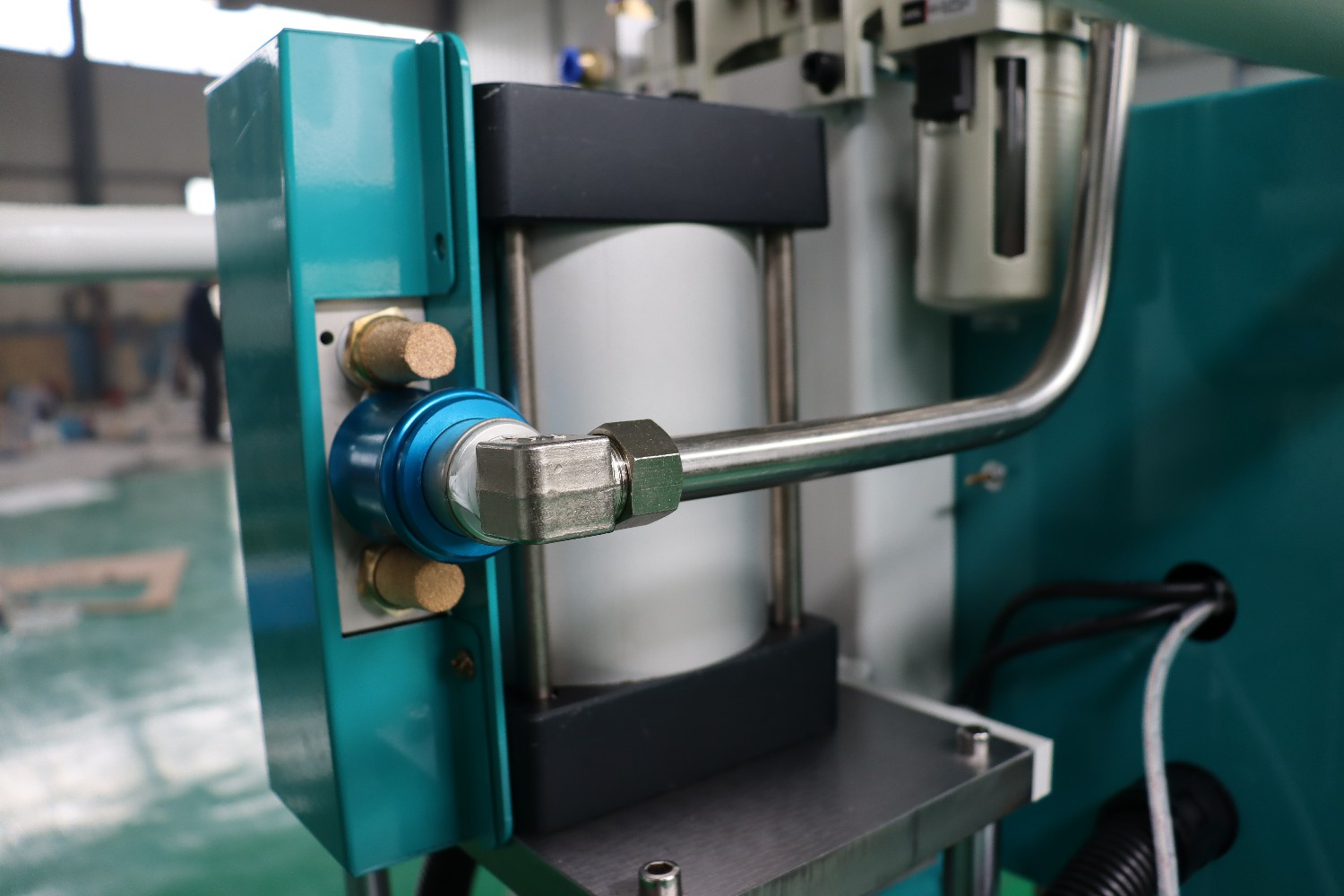

- The big size cylinder makes the spraying more powerful and the atomization effect better.

- Add Voltmeter and Ammeter,so The voltage and current conditions inside the machine can be detected every time

- The electric circuit design is more humanized, engineers can check the circuit problems more quickly

- The heated hose voltage is lower than the human body safety voltage 36v, the operation safety is more higher.

- The machine contains the electric leakage protector to prevent machine leakage and human electric shock, and improve the safety performance of the machine.

- Adpot some technologies from Poly-craft USA brand, heated hose and spray guns can be used on Graco machines and E3 spray machine

| Machine Type | Pneumatic Polyurethane Spray Foam Machine |

| Power source | 110V/220V/380V |

| Heating power | 7.5KW |

| Driven mode | Pneumatic |

| Applicable Industries | Hotels, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Retail, Construction works , Energy & Mining |

| Raw output | 2-12kg/min |

| Core Components | Pump |

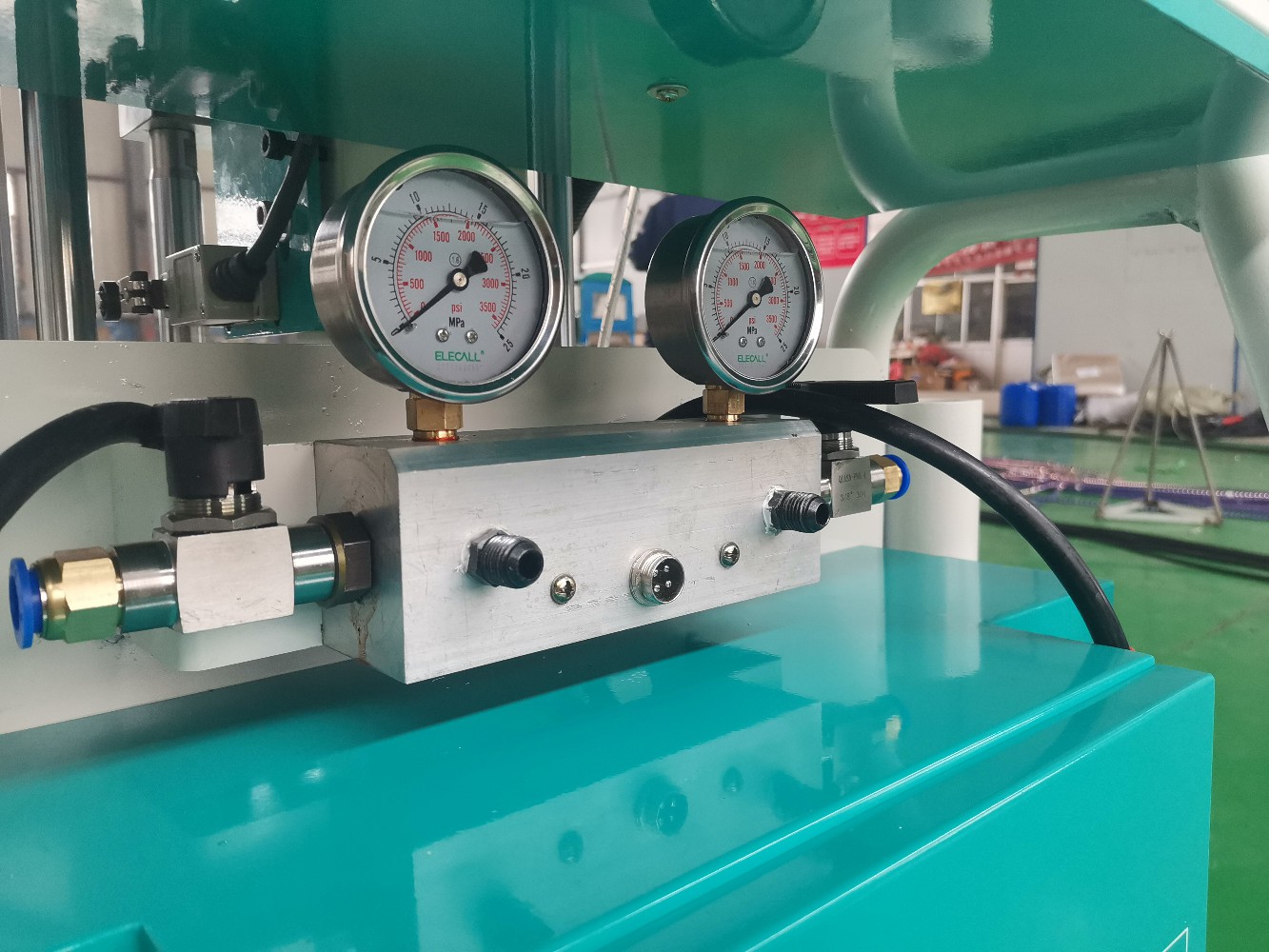

| Max.working pressure | 11MPa |

| A and B chemical output ratio | 1:1 |

| Max hose support | 90 meters |

| Machine size | 75*540*1120mm |

| Machine weight | 139kg |

Widely used in industrial maintenance, tunnels, subways, roadbed waterproofing, foam film and television props production,Pipe anticorrosion, roof waterproof, basement waterproof, wear-resistant lining, external wall insulation, etc.

Write your message here and send it to us