Fully Automatic Hot Melt Adhesive Dispensing Machine Electronic PUR Hot Melt Structural Adhesive Applicator

Feature

1. High-Speed Efficiency: The Hot Melt Glue Dispensing Machine is renowned for its high-speed adhesive application and rapid drying, significantly enhancing production efficiency.

2. Precise Gluing Control: These machines achieve high-precision gluing, ensuring every application is accurate and uniform, eliminating the need for secondary processing.

3. Versatile Applications: Hot Melt Glue Dispensing Machines find applications in various industrial processes, including packaging, carton sealing, bookbinding, woodworking, and cardboard manufacturing.

4. Automated Operation: They often come equipped with automated control systems, allowing presetting of different gluing patterns and modes for intelligent and convenient gluing processes.

5. Excellent Adhesion and Strength: Hot melt glue rapidly cools and solidifies after application, forming strong bonds to ensure secure connections between workpieces.

6. Sustainability: These machines are user-friendly, easy to maintain, and offer sustainable production capacity to meet high-volume demands.

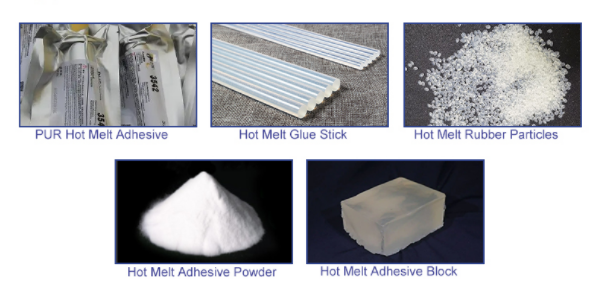

7. Variety of Glue Options: Hot Melt Glue Dispensing Machines can be used with various types of adhesives and hot melt glues to meet the requirements of different projects.

Details

| Model | Dispensing robot | |

| Trip | 300*300*100 / 500*300*300*100 mm | |

| Programing mode | Import teaching programming or graphics | |

| Movable graphics track | Point ,line, are, circle ,curve, multiple lines, spiral, ellipse | |

| Dispensing needle | Plastic needle/TT needle | |

| Dispensing cylinder | 3CC/5CC/10CC/30CC/55CC/100CC/200CC/300CC/500CC | |

| Minimum discharge | 0.01ml | |

| The glue frequency | 5 times/SEC | |

| Load | X/Y axle load | 10kg |

| Z axle load | 5kg | |

| Axial dynamic speed | 0~600mm/sec | |

| Resolving power | 0.01mm/Axis | |

| Repeated positioning accuracy | Screw drive | 0.01 ~0.02 |

| synchronous belt drive | 0.02 ~0.04 | |

| Program record mode | At least 100 groups, 5000Points each | |

| Display mode | LCD teaching box | |

| Motor system | Japan precision micro stepping motor | |

| Drive mode | Guide | Taiwan upper silver linear guide rail |

| Wire rod | Taiwan silver bar | |

| Belt | Italy Lartey synchronous belt | |

| X/Y/Z axis synchronous belt for standard configuration, Z axis screw rod is optional, X/Y/Z axis screw rod for customization | ||

| Motion filling function | Three dimensional space any route | |

| Input power | Full voltage AC110~220V | |

| External control interface | RS232 | |

| Motor control shaft number | 3 axis | |

| Axis range | X axis | 300(Customized) |

| Y axis | 300 (Customized) | |

| Z axis | 100(Customized) | |

| R axis | 360°(Customized) | |

| Outline size(mm) | 540*590*630mm / 740*590*630mm | |

| Weight (kg) | 48kg / 68kg | |

- Packaging and Sealing: In the packaging industry, Hot Melt Glue Dispensing Machines are used for sealing boxes, bags, and packaging containers, ensuring the secure and intact packaging of products.

- Bookbinding: In the printing industry, these machines are employed for bookbinding, ensuring firm bonding of book pages to create high-quality books.

- Woodworking: The woodworking industry utilizes Hot Melt Glue Dispensing Machines for furniture assembly and wood bonding, ensuring strong connections between components and structural stability.

- Carton Manufacturing: In the production of cardboard boxes and paper products, Hot Melt Glue Dispensing Machines are used for bonding cardboard to create durable packaging materials.

- Automotive Manufacturing: The automotive industry employs these machines for applying adhesive to automotive interior parts and sealants, ensuring the quality and performance of automotive components.

- Electronics Assembly: In electronics manufacturing, Hot Melt Glue Dispensing Machines are used for the fixation and bonding of electronic components, ensuring secure connections between circuit boards and components.

- Footwear Industry: In shoe manufacturing, these machines are used for bonding shoe soles and uppers, ensuring footwear quality and appearance.

- Medical Device Assembly: The medical industry utilizes Hot Melt Glue Dispensing Machines for assembling medical devices, ensuring high hygiene and quality standards.

- Paper Products and Label Manufacturing: Used in the production of labels, stickers, and other paper products, ensuring strong adhesion.