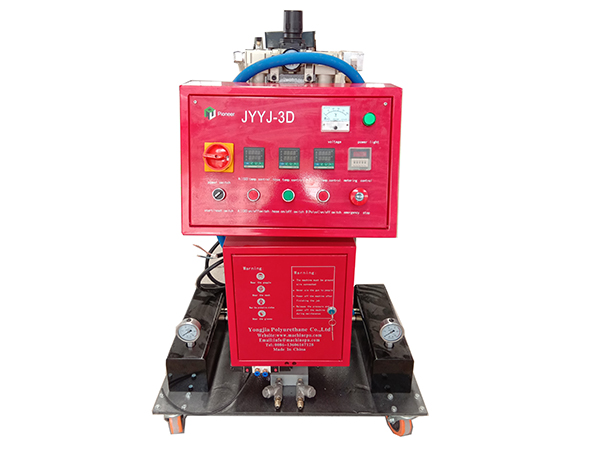

JYYJ-3D Polyurethane Insulation Foam Spray Machine For Internal Wall Insulation

Feature

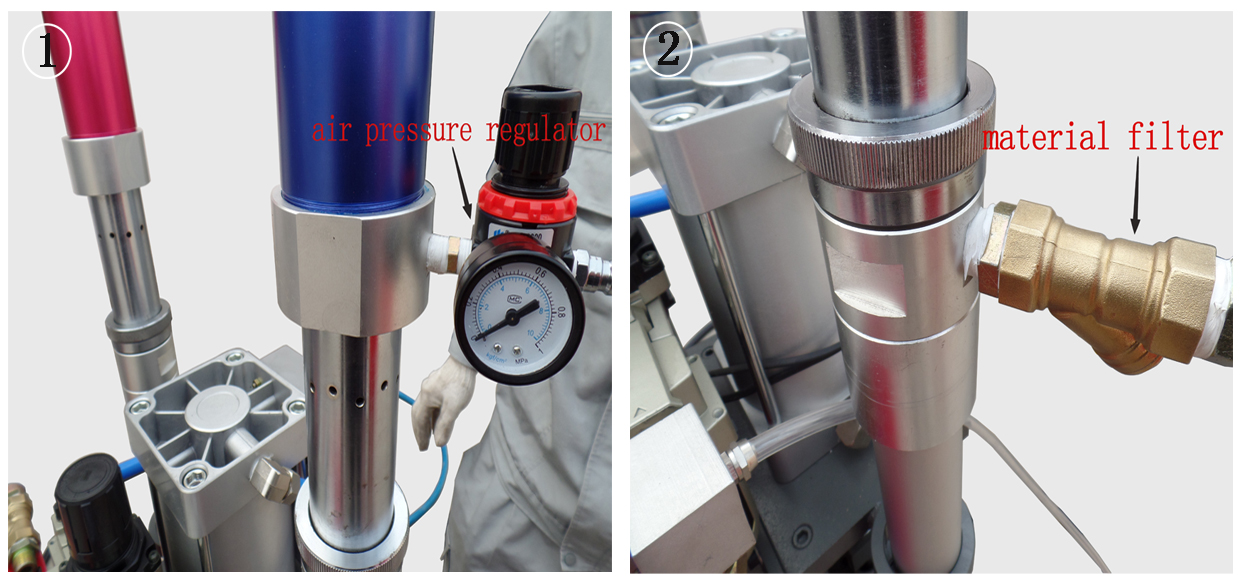

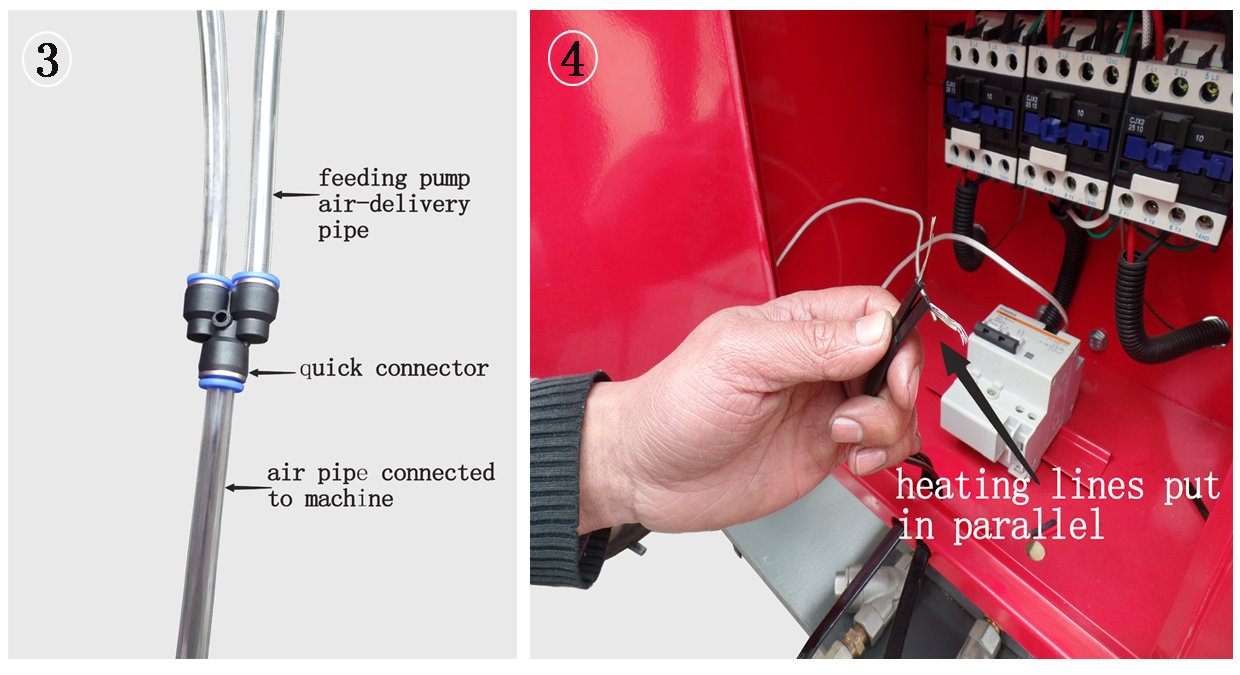

1.Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;

2. Lifting pump adopts big change ratio method, the winter also can easily feed raw materials high viscosity

3. Feed rate can be adjusted,have time-set,quantity-set features, suitable for batch casting, improve production efficiency;

4. With small volume, light weight, low failure rate, easy operation and other great features;

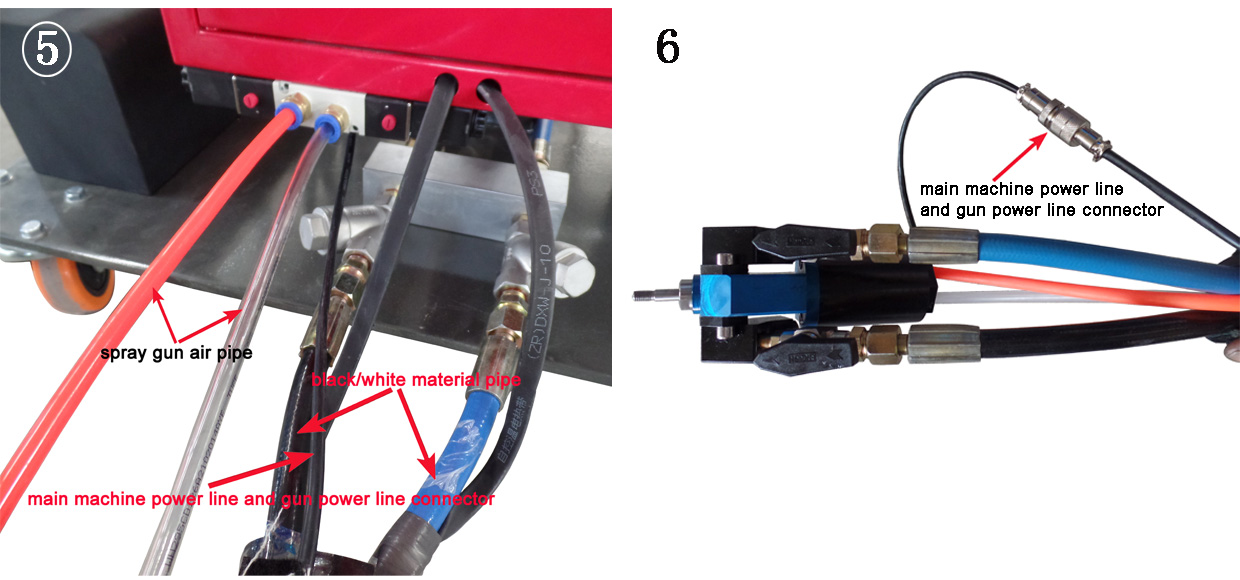

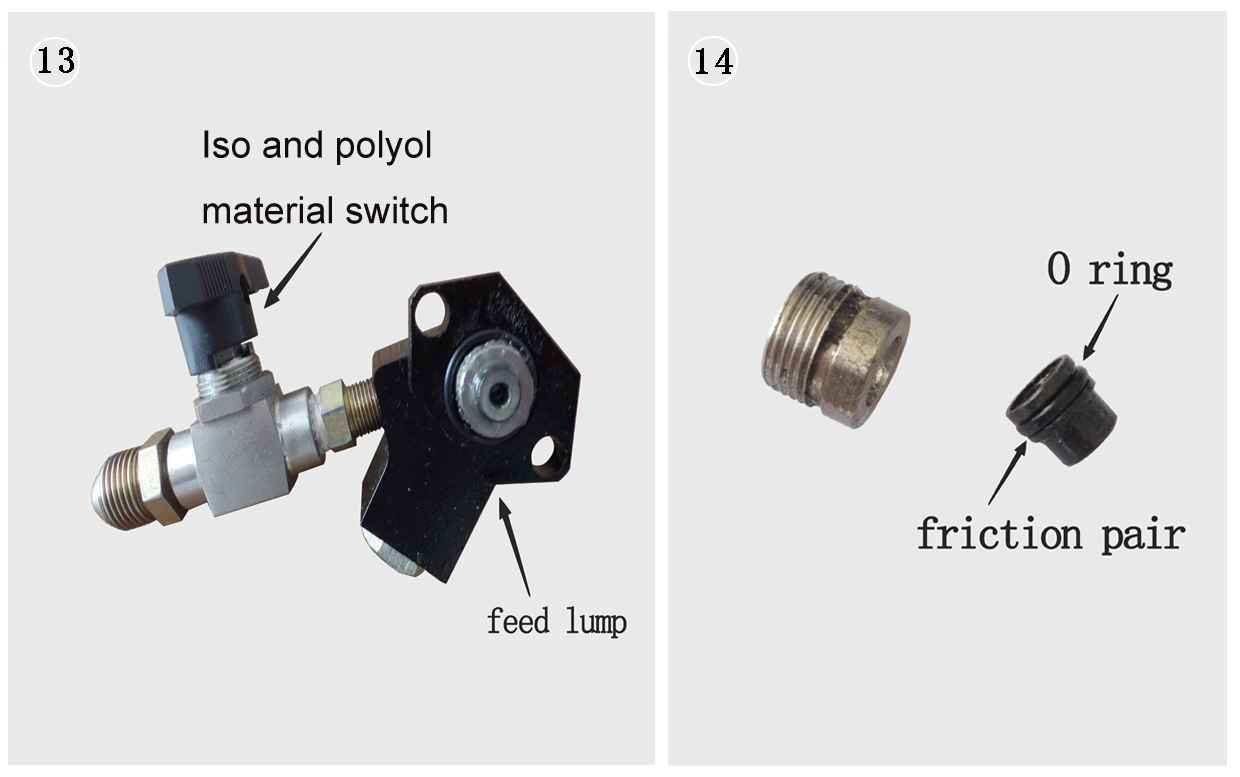

5. Secondary pressurized device to ensure fixed material proportion of equipment, improve product yield;

6. Multi-leakage protection system to protect the safety of the operator;

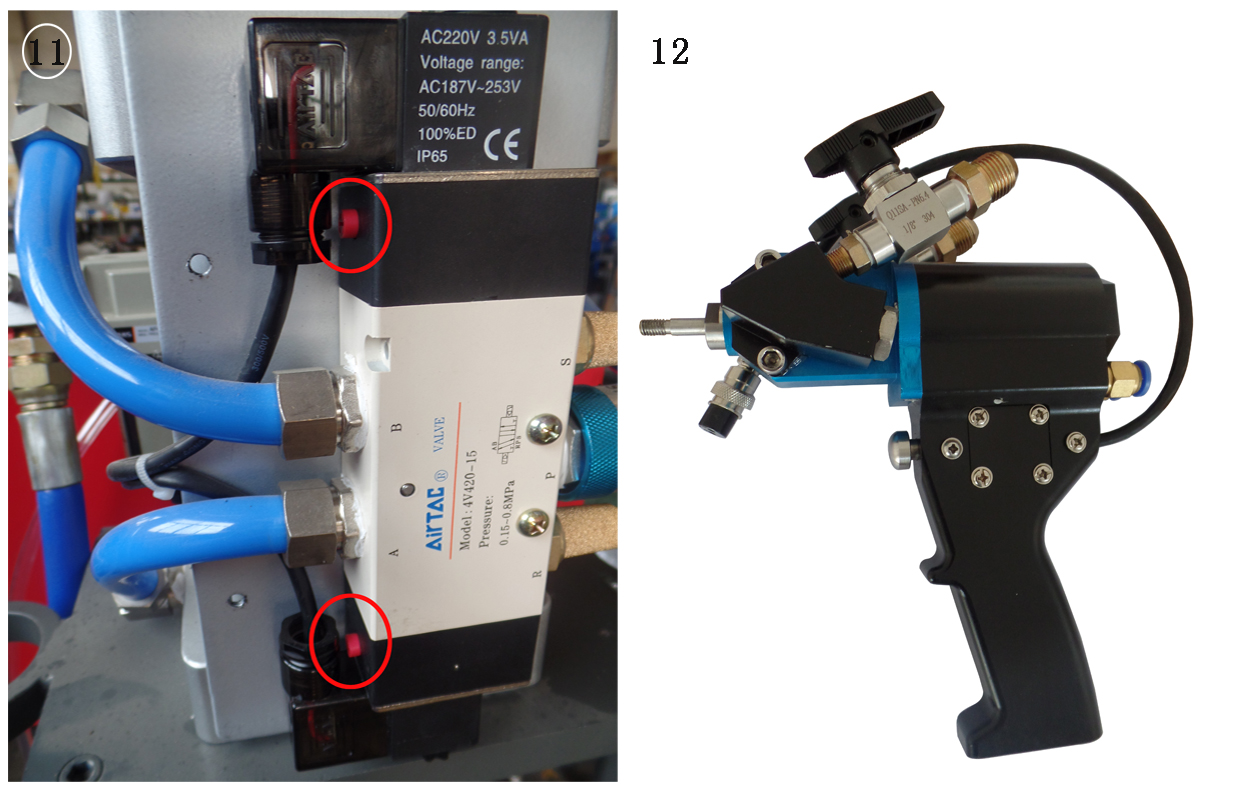

7. Equipped with emergency switch system, help operator deal with emergencies rapidly;

8. Humanized design with equipment operation panel, super easy to get the hang of it;

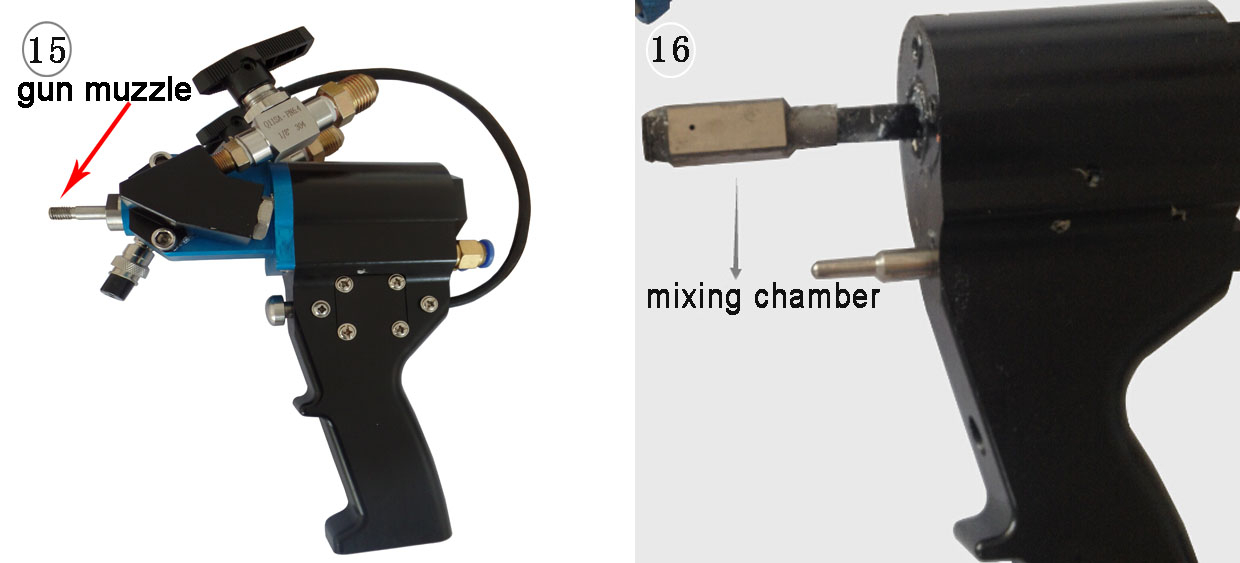

9. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;

10.Minimizing spraying congestion with multi-feedstock device.

| Power source | single phase 220V 50Hz |

| Heating power | 7.5KW |

| Driven mode | pneumatic |

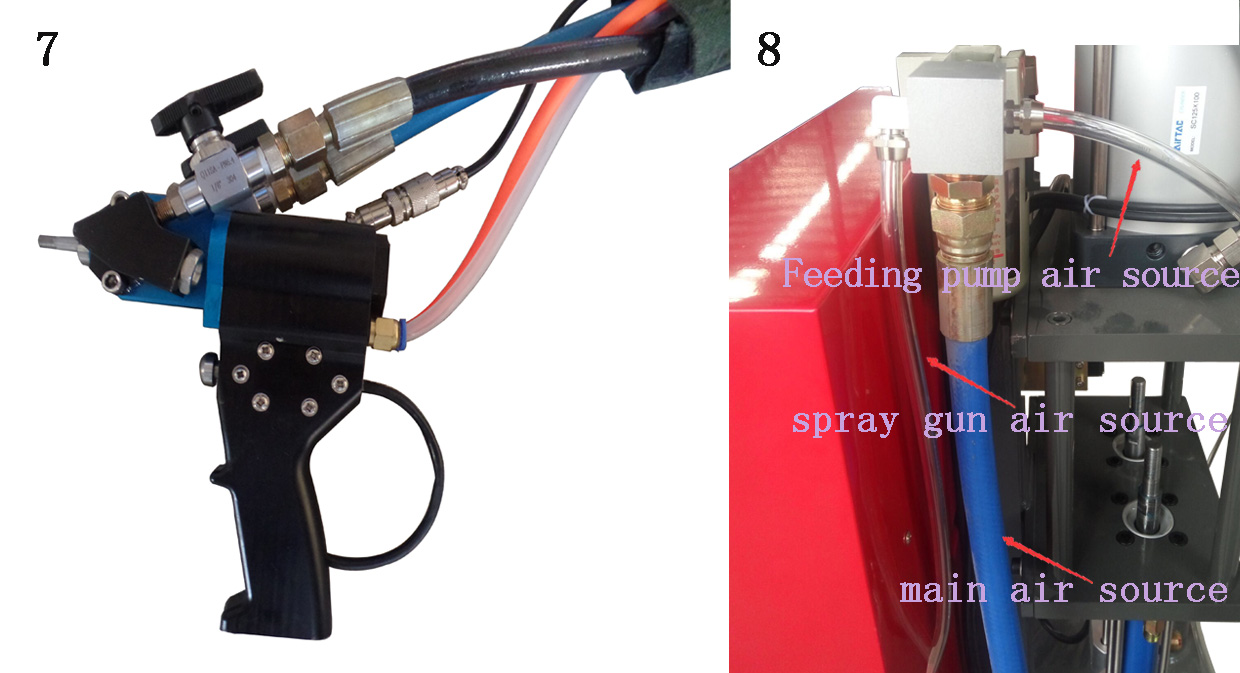

| Air source | 0.5~0.8 MPa ≥0.9m3/min |

| Raw output | 2~12 kg/min |

| Maximum output pressure | 11Mpa |

| AB material output ratio | AB 1:1 |

1. Insulation & Coating: external wall insulation, internal wall insulation, roof, cold storage, ship cabin, cargo containers,trucks, refrigerated trucks,tank, etc.

2. Casting: solar water heaters,tank insulation, cabin, insulation board, security doors, refrigerators, pipes, road construction, packaging, road construction, wall insulation, etc.