PUR PU Polyurethane Foam Filling High Pressure Machine For 3D Wall Panel Making

Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyurethane and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

Product Features of High Pressure PU Machine:

1.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3.Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

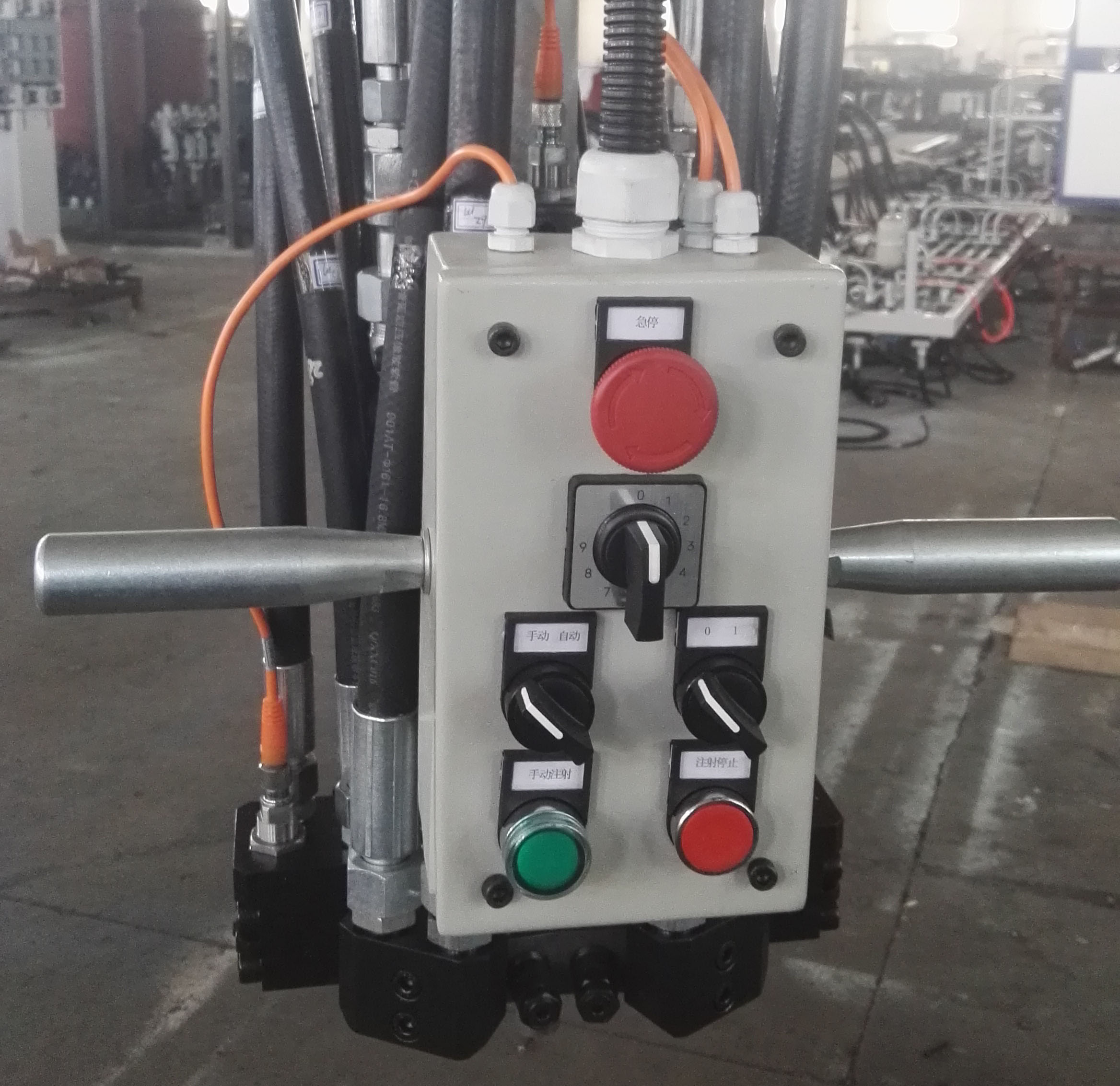

6.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

Material tank: Poly/ Iso tank with 500L, thermostatic control by two layer wall with insulation layer, installing two manual stop valves in delivery outlet,bottom installed with waste valve.

Mixing head: Adopt L type automatic self-cleaning mixing head, needle type nozzle adjustable, V type jet orifice, High-pressure collisional mixing principle ensure mixing effectual.

Chiller: Used to supply cooling water to cooling unit,refrigeration capacity 38700Kcal/h ;(options)

| No. | Item | Technical parameter |

| 1 | Foam application | Flexible Foam |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPas

ISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 280~1300g/min |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/min

System pressure 10~20MPa |

| 11 | Tank volume | 500L |

| 15 | Temperature control system | Heat: 2×9Kw |

| 16 | Input power | Three-phase five-wire 380V |

Compared with other background walls, the soft 3D PU background wall has a very soft texture and soft color, which can well soften the overall space atmosphere in a decorative environment. Due to the special craftsmanship of the soft-covered background wall, including the characteristics and luxury of the material used, it has greatly improved the grade of the entire home space. In addition, the three-dimensional sense of the soft-covered background wall can also greatly improve the grade of the home space. . In addition to the function of beautifying the space, the soft-packed background wall has the functions of sound absorption, sound insulation, anti-collision, shock resistance, fire and flame retardant. The soft background wall is not only beautiful but also very practical.