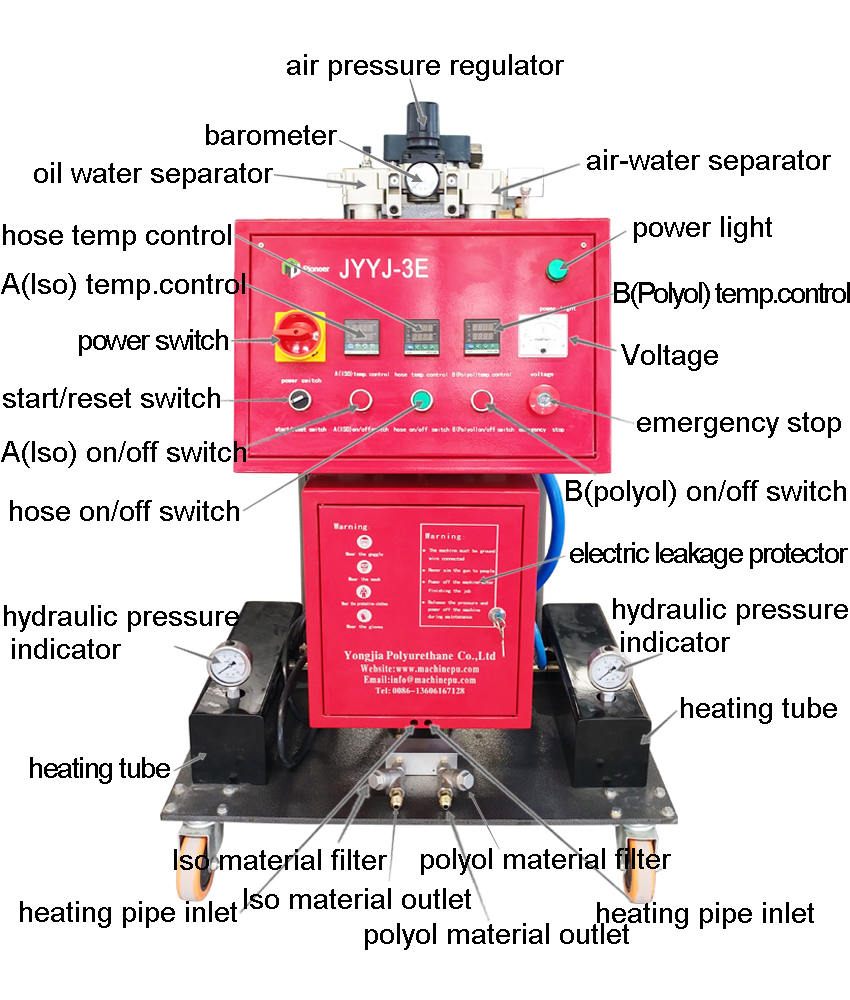

JYYJ-3E Polyurethane Foam Spray Machine

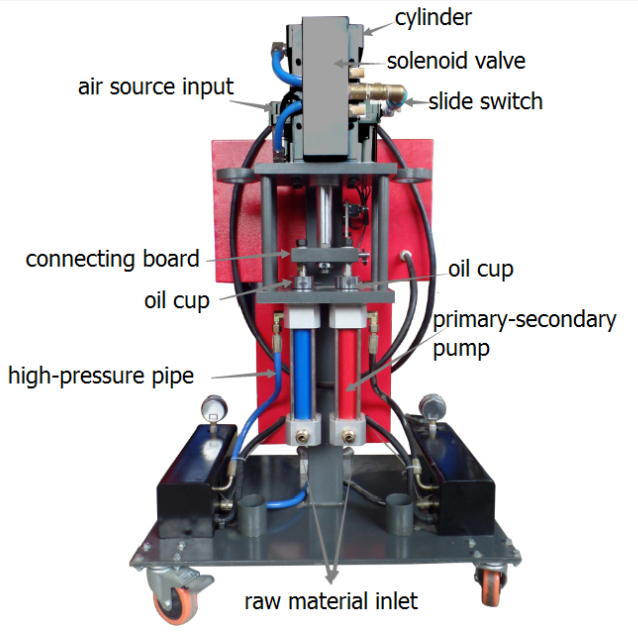

- With 160 cylinder pressurizer, easy to provide sufficient work pressure;

- Small size, light weight, low failure rate, easy operation, easy to move;

- The most advanced air change mode maximally ensures the equipment stability;

- Quadruple raw material filter device maximally reduce blocking issue;

- Multiple leakage protection system safeguard operator’s safety;

- Emergency switch system fasten the dealing with emergencies;

- Reliable and powerful 380v heating system can heat up materials to ideal state rapidly to ensure normal construction in cold region;

- Digital display counting system can accurately know about the raw material consumption status in time;

- Humanization setting equipment operation panel, easy operation mode;

- The latest spray gun has small size, light weight and low failure rate;

- The lifting pump has big mix ratio adjusting range, which can easily feed high viscosity material in cold weather.

|

Parameter |

Power source |

1- phase 220V 50HZ |

|

Heating power |

7.5KW |

|

|

Driven mode |

pneumatic |

|

|

Air source |

0.5-0.8 MPa ≥0.9m³/min |

|

|

Raw output |

2-12 kg/min |

|

|

Maximum output pressure |

11MPA |

|

|

Poly and ISO material output ratio |

1:1 |

|

|

Spare parts |

Spray gun |

1 Set |

|

Heating hose |

15-120 meters |

|

|

Spray gun connector |

2 m |

|

|

Accessories box |

1 |

|

|

Instruction book |

1 |

The spray foaming machine is widely used in embankment waterproof, pipeline corrosion, auxiliary cofferdam, tanks, pipe coating, cement layer protection, wastewater disposal, roofing, basement waterproofing, industrial maintenance, wear-resistant linings, cold storage insulation, wall insulation and so on.

Write your message here and send it to us