Industrial Electric Servo Motors Pneumatic Paint Air Industrial Sand Electric Drum Rotary High-quality Motor Mixing Tank Agitator Mixer

1. Using compressed air as the power source and air motor as the power medium, no sparks will be generated during long-term operation, explosion-proof, safe and reliable.

2. The air motor can run for a long time, and the temperature rise is small; it will not burn the motor due to overload, and will not generate sparks.

3. The mixer can run at full load. When it is overloaded, it will only slow down or stop the speed. Once the load is removed, it will resume operation, and the mechanical failure rate is low.

4. With high starting torque, it can start directly with load. Start and stop are quick.

5. The air motor has a stepless speed regulation function, and the speed can be adjusted easily by adjusting the size and pressure of the intake air.

6. Can realize forward and reverse operation; forward and reverse can be easily realized by changing the direction of air intake.

7. It can work continuously and safely in harsh working conditions such as flammable, explosive, high temperature, and high humidity.

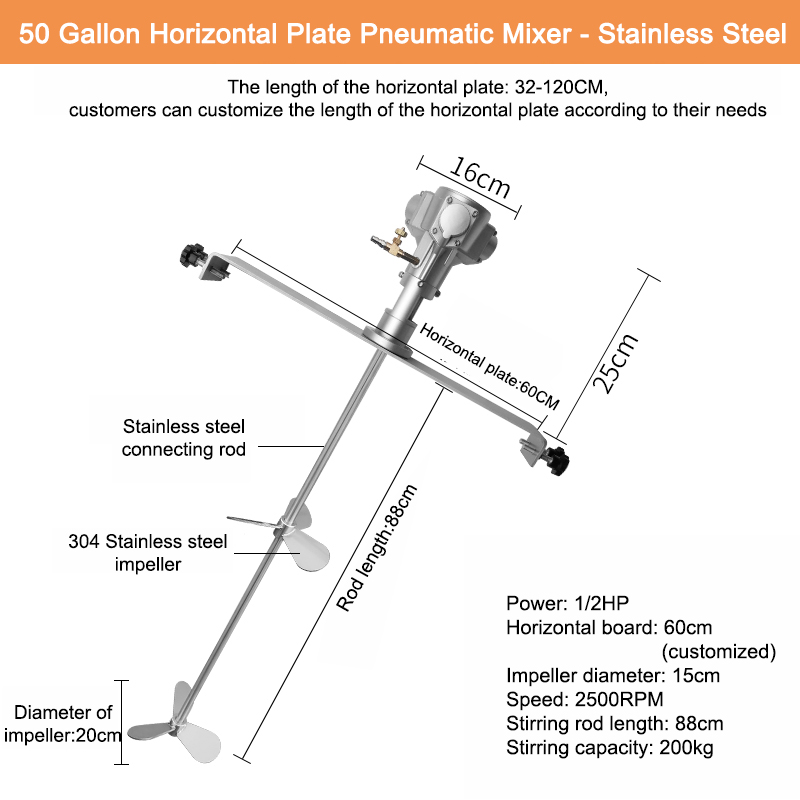

8. The part in contact with the liquid is made of SUS304# stainless steel; it has good corrosion resistance, acid and alkali resistance.

9. The structure of the pneumatic mixer is simple, and the connecting rod and paddle are fixed by screws; it is easy to disassemble and assemble; and the maintenance is simple.

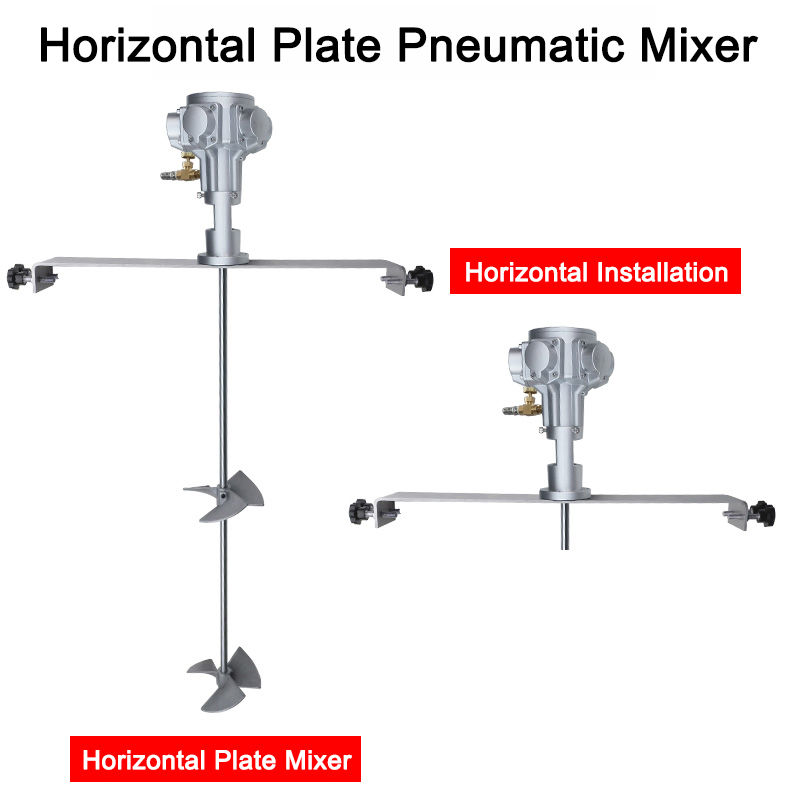

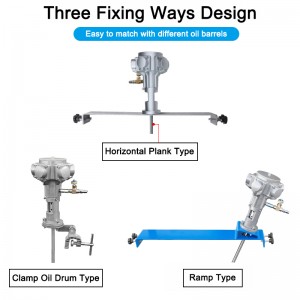

10. The fixed horizontal plate is directly mounted on the open material barrel, which is simple, convenient and economical.

11. The fixed horizontal plate is made of carbon steel, the surface is pickled, phosphated and painted, and two M8 are equipped at each end of the horizontal plate

The handle screw is fixed, and there will be no movement or movement when stirring.

12. The horizontal plate pneumatic mixer is light in weight, easy to carry and takes up little space.

13. The horizontal plate pneumatic mixer is equipped with 2 layers of three-blade mixing impellers, which can stir evenly up and down at the same time.

| Power | 1/2HP |

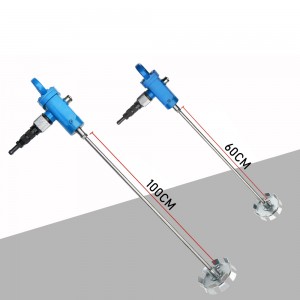

| Horizontal board | 60cm(customized) |

| Impeller diameter | 15cm |

| Speed | 2500RPM |

| Stirring rod length | 88cm |

| Stirring capacity | 200kg |

Widely used in coatings, paints, solvents, inks, chemicals, food, beverages, medicines, rubber, leather, glue, wood, ceramics, emulsions, greases, oils, lubricating oils, epoxy resins and other open materials with medium and low viscosity liquids bucket mixing