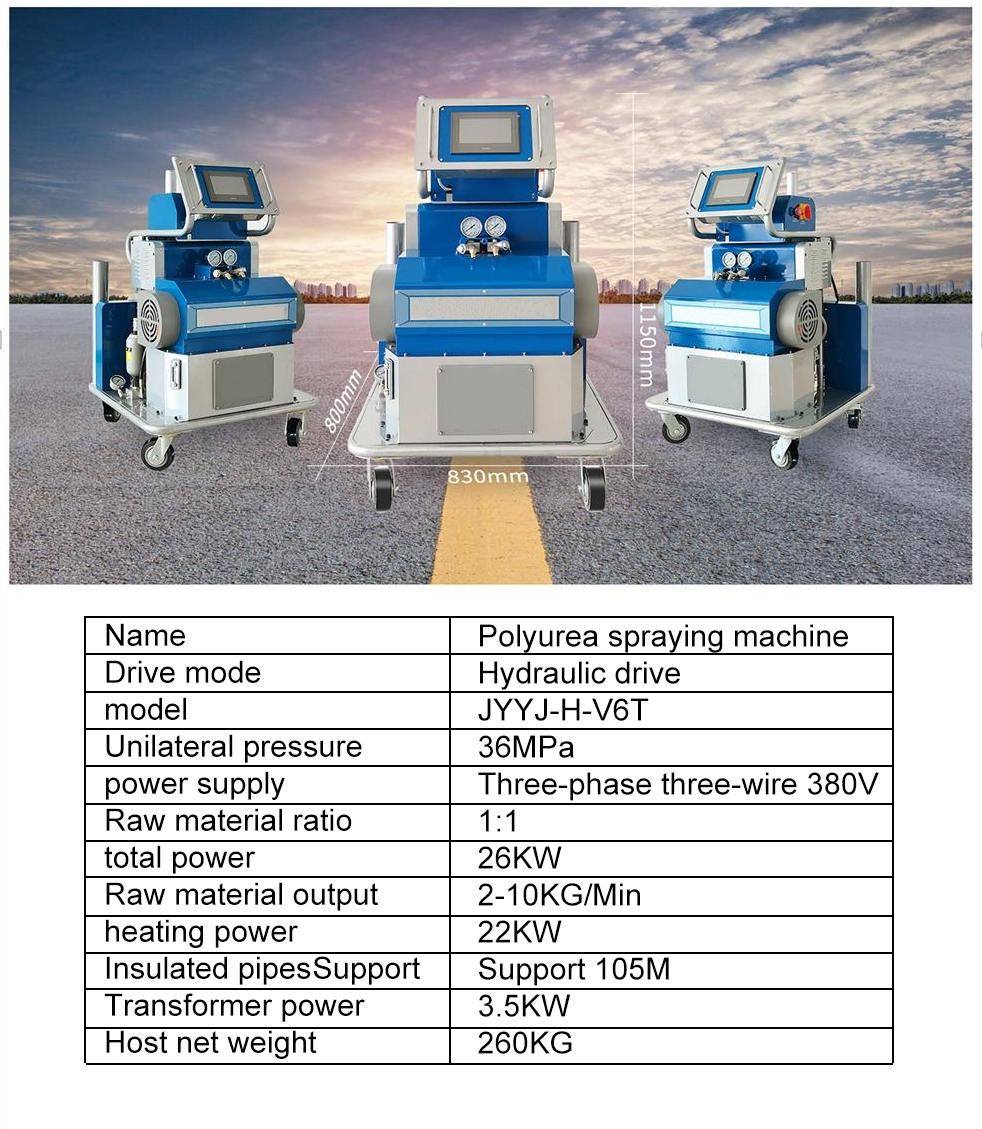

JYYJ-H-V6T Spray Foam Insulation Polyurethane Sprayer

- Technological Leadership: We lead innovation in polyurethane coating technology, continually enhancing product performance to meet diverse coating needs.

- High Performance: Our Polyurethane Spray Machine is renowned for its high performance and durability, ensuring optimal coating results for your projects.

- Flexibility: Suitable for various materials and surfaces, it exhibits outstanding adaptability, ensuring seamless performance across different projects.

- Reliability: Designed for stability and durability, it guarantees reliability under various working conditions, reducing maintenance costs.

- Efficient Spraying Technology: Our Polyurethane Spray Machine employs advanced technology to ensure an efficient and uniform coating process. Whether it’s large-scale construction projects or precision manufacturing, it excels in performance.

- Smart Control System: Equipped with an intelligent control system, users can easily adjust coating parameters to meet personalized coating requirements. The automation enhances operational efficiency, reducing complexity.

- Versatile Applications: Suitable for industries such as construction, automotive, furniture, and more. The multifunctionality of polyurethane coating makes it an ideal choice for various coating needs.

- Precision Spraying: This spray machine stands out for its precise coating, covering flat surfaces or complex structures with accuracy, enhancing project quality.

- Building Insulation: In the construction industry, our Polyurethane Spray Machine is used to achieve efficient insulation coatings, enhancing the energy efficiency of buildings.

- Automotive Manufacturing: Applied for external coatings in automotive manufacturing, ensuring the uniformity and durability of coatings, improving the appearance and protective performance of vehicles.

- Furniture Manufacturing: In the furniture industry, polyurethane coating ensures a uniform and durable coating on wood surfaces, enhancing product aesthetics.

- Industrial Coating: Suitable for large-scale industrial coating projects, ensuring efficient coating and improving production efficiency.

Write your message here and send it to us