PU High Preasure Earplug Making Machine Polyurethane Foaming Machine

Polyurethane high pressure foaming equipment. As long as the polyurethane component raw materials (isocyanate component and polyether polyol component) performance indicators meet the formula requirements. Through this equipment, uniform and qualified foam products can be produced. Polyether polyol and polyisocyanate are foamed by chemical reaction in the presence of various chemical additives such as foaming agent, catalyst and emulsifier to obtain polyurethane foam.

Polyurethane foaming machine can be used for automobile interior decoration, thermal insulation wall spraying, thermal insulation pipe manufacturing, bicycle and motorcycle seat sponge, etc.

Features

1.This equipment is mainly used for the production of thermal insulation pipes, thermal insulation boards, refrigerators and other products with high PU input.

2.This equipment is equipped with imported special metering pump, magnetic coupling and German high-precision flowmeter, with high injection accuracy and repeatability.

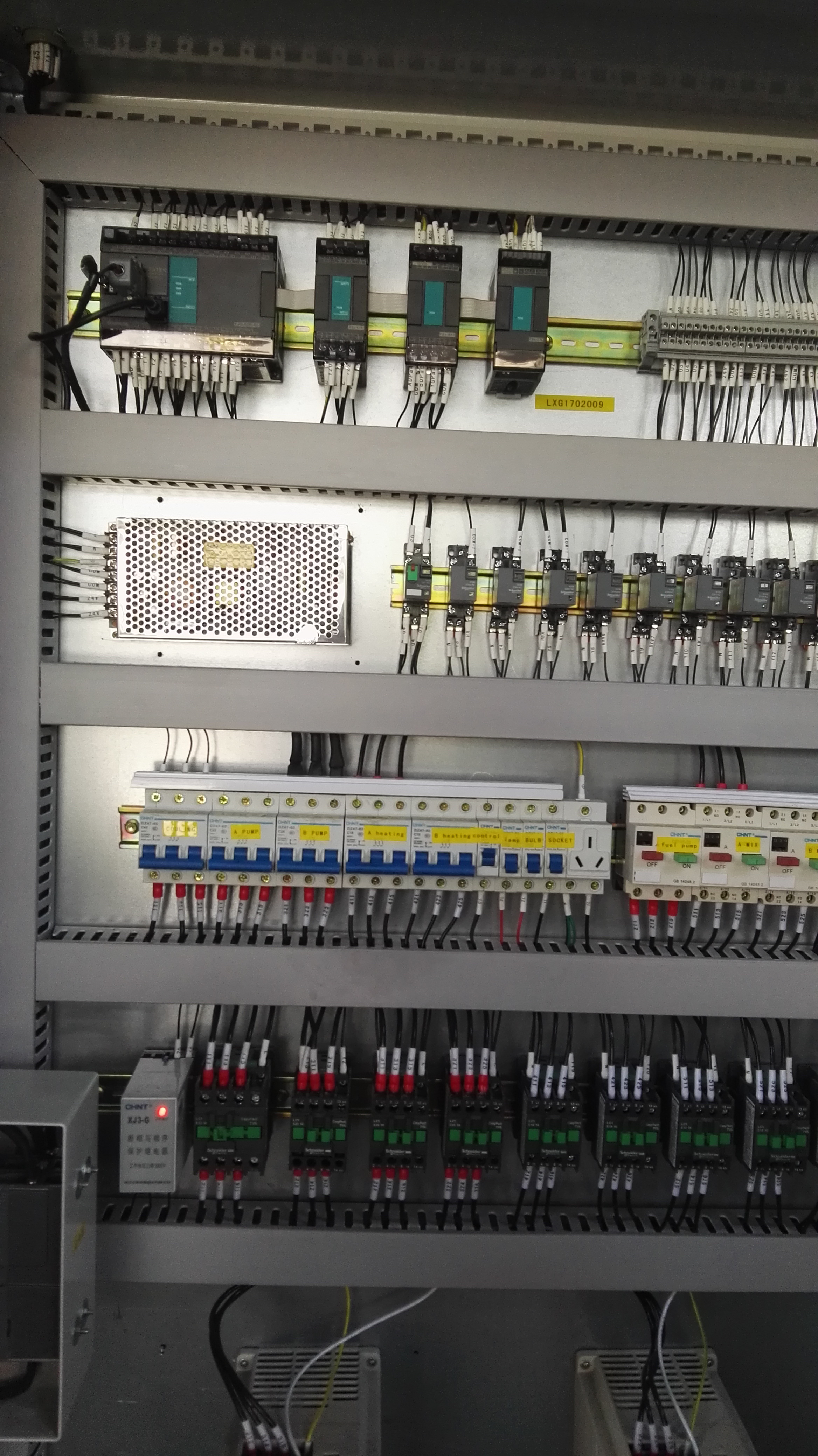

3.The equipment adopts PLC control and is equipped with a man-machine interface, which can monitor the entire equipment system, automatically judge when abnormal, and provide diagnostic information; it adopts German safety control system and is equipped with production statistics function.

4.This equipment can be expanded into a multi-tip production system to reduce input costs.

| Processing Type: | Foaming Machine, Foaming Machine | Condition: | New |

|---|---|---|---|

| Product Type: | Foam Net | Voltage: | 380V |

| Dimension(L*W*H): | 4100(L)*1250(W)*2300(H)mm | Warranty: | 1 YEAR |

| After-sales Service Provided: | Video Technical Support, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Online Support | Key Selling Points: | Automatic |

| Applicable Industries: | Manufacturing Plant | Strength 1: | Self-cleaning Filter |

| Strength 2: | Automatic Feeding System | Strength 3: | PLC Control System |

| Strength 4: | Precise Metering | Foam Type: | Flexible Foam |

| Output: | 16-66g/s | Tank Volume: | 120L |

| Power: | Three-phase Five-wire 380V | Name: | Polyurethane Machine |

| Power: | About 9 KW | Weight: | About 1000kg |

| Port: | Ningbo For Polyurethane Foam Machine | ||

| High Light: |

120L High Pressure PU Foaming Machine120L pu foam making machineSS304 High Pressure PU Foaming Machine |

||

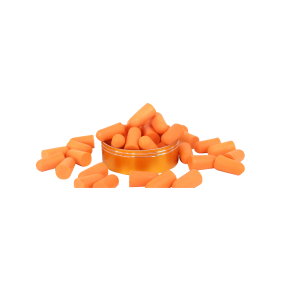

Polyurethane earplugs have good slow rebound characteristics, which can better fit people’s ear canals and play an effective noise reduction role. You can simply do a slow rebound test on the earplugs, squeeze the earplugs hard, and observe the gradual rebound of the earplugs after letting go. It can be expanded and recovered in a short time. Its softness and breathability are better, and it is more comfortable to wear.