PU Stress Ball Toys Foam Injection Machine

PU polyurethane ball production line specializes in the production of various types of polyurethane stress balls, such as PU golf, basketball, football, baseball, tennis and children’s hollow plastic bowling. This PU ball is vivid in color, cute in shape, smooth in surface, good in rebound, long in service life, suitable for people of all ages, and can also customize LOGO, style color size. PU balls are popular with the public and are now very popular.

PU low/high pressure foam machine Features:

1, High precision bent-axial type constant delivery pumps, accurate measurement, stable operation;

2, Magnetic coupling coupler with high tech permanent magnetic control, no temperature rise, no leakage;

3, High precision self clean high-pressure mixing head, high pressure injection, and impingement mixing, extremely high mixing uniformity, use no scrap, free cleaning, maintenance free. High strength material manufacturing, long service life;

4, AB material needle valves locked after balanced, ensuring no difference between AB material pressure;

5, Mixing head adopts double proximity switch control interlock function;

6, Raw material timing cycle function ensures no crystallization during downtime;

7, Full digitalization, modular integrated control all process flow, accurate, safe, intuitive, intelligent, humanization.

Machine Details

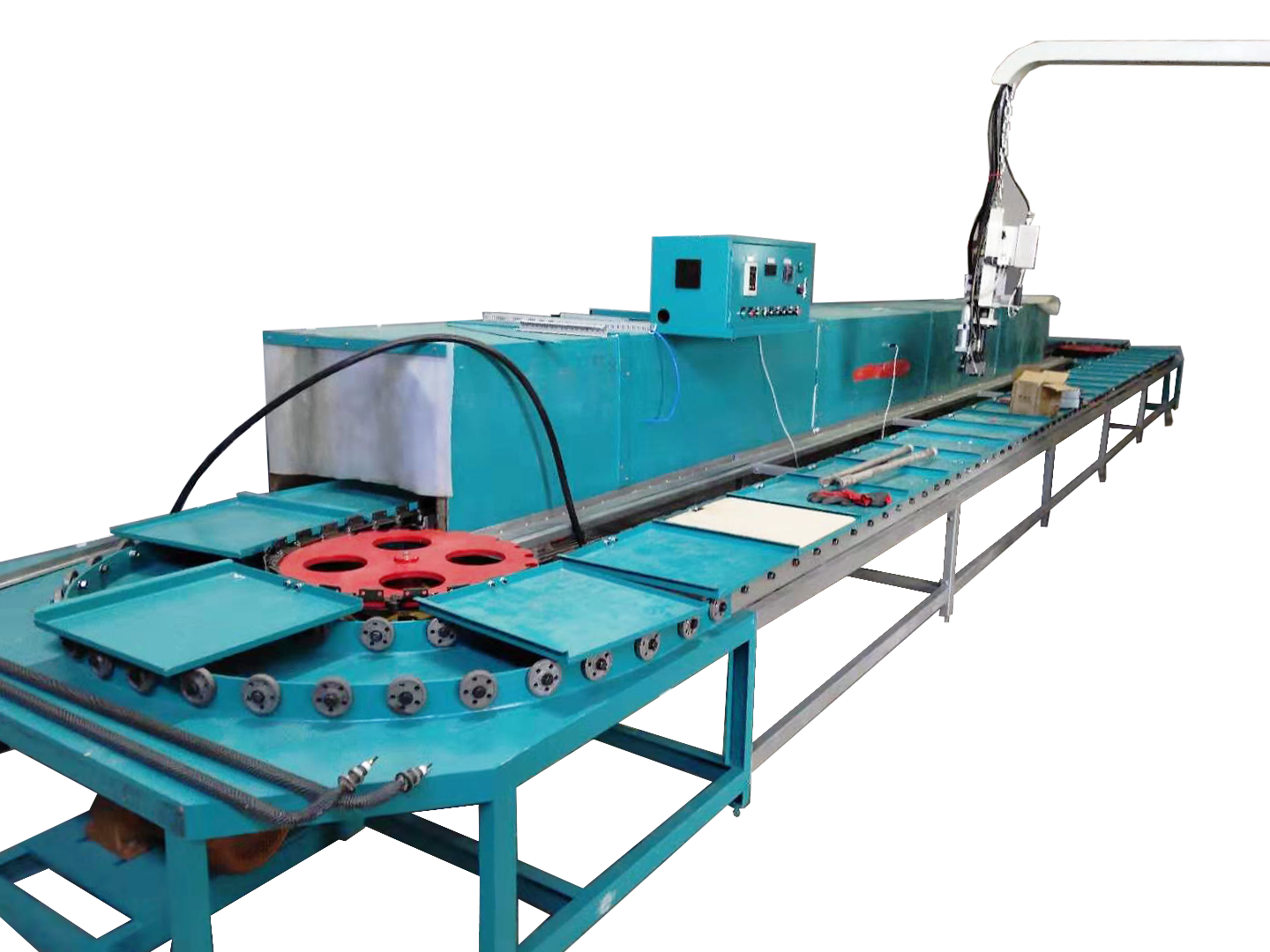

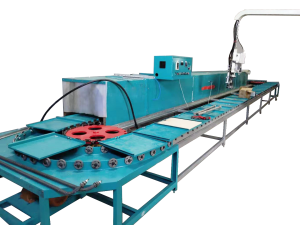

Ring production line:

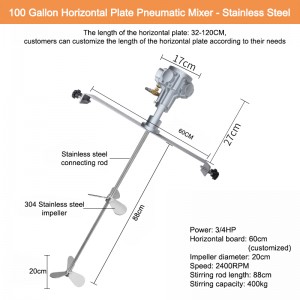

Low Pressure Foam Pouring Machine:

Stress Toy Molds:

More machine needed in this production line welcome to consult us!

Specification

|

No. |

Item |

Technical Parameter of low pressure foam machine |

|

1 |

Foam application |

Flexible foam |

|

2 |

raw material viscosity(22℃) |

Polyol~3000CPS ISOCYANATE ~1000MPas |

|

3 |

Injection Output |

9.4-37.4g/s |

|

4 |

Mixing ratio range |

100:28~48 |

|

5 |

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

6 |

Tank Volume |

120L |

|

7 |

Metering pump |

A pump: JR12 Type B Pump: JR6 Type |

|

8 |

Compressed air requirement |

dry, oil free P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

|

9 |

Nitrogen requirement |

P:0.05MPa Q:600NL/min(Customer-owned) |

|

10 |

Temperature control system |

heat:2×3.2kW |

|

11 |

Input power |

three-phrase five-wire,380V 50HZ |

|

12 |

Rated power |

about 9KW |

Application

Rubber foam toy balls, polyurethane foam balls, foam children’s toy balls, and foam educational toy balls are made of natural rubber, with a smooth surface, soft and comfortable feel, vivid and vivid colors, beautiful and cute appearance, durable and resilient Good, safe and non-toxic, with many styles and various sizes.

Ring production line:

Low Pressure Foam Pouring Machine:

Stress Toy Molds:

More machine needed in this production line welcome to consult us!

|

No. |

Item |

Technical Parameter of low pressure foam machine |

|

1 |

Foam application |

Flexible foam |

|

2 |

raw material viscosity(22℃) |

Polyol~3000CPS ISOCYANATE ~1000MPas |

|

3 |

Injection Output |

9.4-37.4g/s |

|

4 |

Mixing ratio range |

100:28~48 |

|

5 |

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

6 |

Tank Volume |

120L |

|

7 |

Metering pump |

A pump: JR12 Type B Pump: JR6 Type |

|

8 |

Compressed air requirement |

dry, oil free P:0.6-0.8MPa Q:600NL/min(Customer-owned) |

|

9 |

Nitrogen requirement |

P:0.05MPa Q:600NL/min(Customer-owned) |

|

10 |

Temperature control system |

heat:2×3.2kW |

|

11 |

Input power |

three-phrase five-wire,380V 50HZ |

|

12 |

Rated power |

about 9KW |

Rubber foam toy balls, polyurethane foam balls, foam children’s toy balls, and foam educational toy balls are made of natural rubber, with a smooth surface, soft and comfortable feel, vivid and vivid colors, beautiful and cute appearance, durable and resilient Good, safe and non-toxic, with many styles and various sizes.