Decorative Cornice Foaming Polyurethane Crown Molding Injection Machine

Polyurethane foaming machine, has the economical, convenient operation and maintenance, etc, can be customized according to customer’s request various pours out of the machine.

This polyurethane foaming machine uses two raw materials, polyurethane and Isocyanate. This type of PU foam machine can be used in various industries, such as daily necessities, automobile decoration, medical equipment, sports industry, leather footwear, packaging industry, furniture industry, military industry.

Product Features of High Pressure PU Machine:

1.Adopting three layer storage tank, stainless steel liner, sandwich type heating, outer wrapped with insulation layer, temperature adjustable, safe and energy saving;

2.Adding material sample test system, which can be switched freely without affecting normal production, saves time and material;

3.Low speed high precision metering pump, accurate ratio, random error within ±0.5%;

4.Material flow rate and presure adjusted by converter motor with variable frequency regulation, high accuracy, simple and rapid ration adjusting;

5.High-performance mixed device, accurately synchronous materials output, even mixture. New leakproof structure, cold water cycle interface reserved to ensure no blockage during long downtime;

6.Adopting PLC and touch screen man-machine interface to control the injection, automatic cleaning and air flush, stable performance, high operability, automatically distinguish, diagnose and alarm abnormal situation, display abnormal factors.

| No. | Item | Technical parameter |

| 1 | Foam application | Decoration Crown Moldings |

| 2 | Raw material viscosity(22℃) | POLY ~2500MPasISO ~1000MPas |

| 3 | Injection pressure | 10-20Mpa(adjustable) |

| 4 | Output (mixing ratio 1:1) | 160~800g/s |

| 5 | Mixing ratio range | 1:5~5:1(adjustable) |

| 6 | Injection time | 0.5~99.99S(correct to 0.01S) |

| 7 | Material temperature controlling error | ±2℃ |

| 8 | Repeat injection accuracy | ±1% |

| 9 | Mixing head | Four oil house,double oil cylinder |

| 10 | Hydraulic system | Output: 10L/minSystem pressure 10~20MPa |

| 11 | Tank volume | 250L |

| 12 | Input power | Three-phase five-wire 380V |

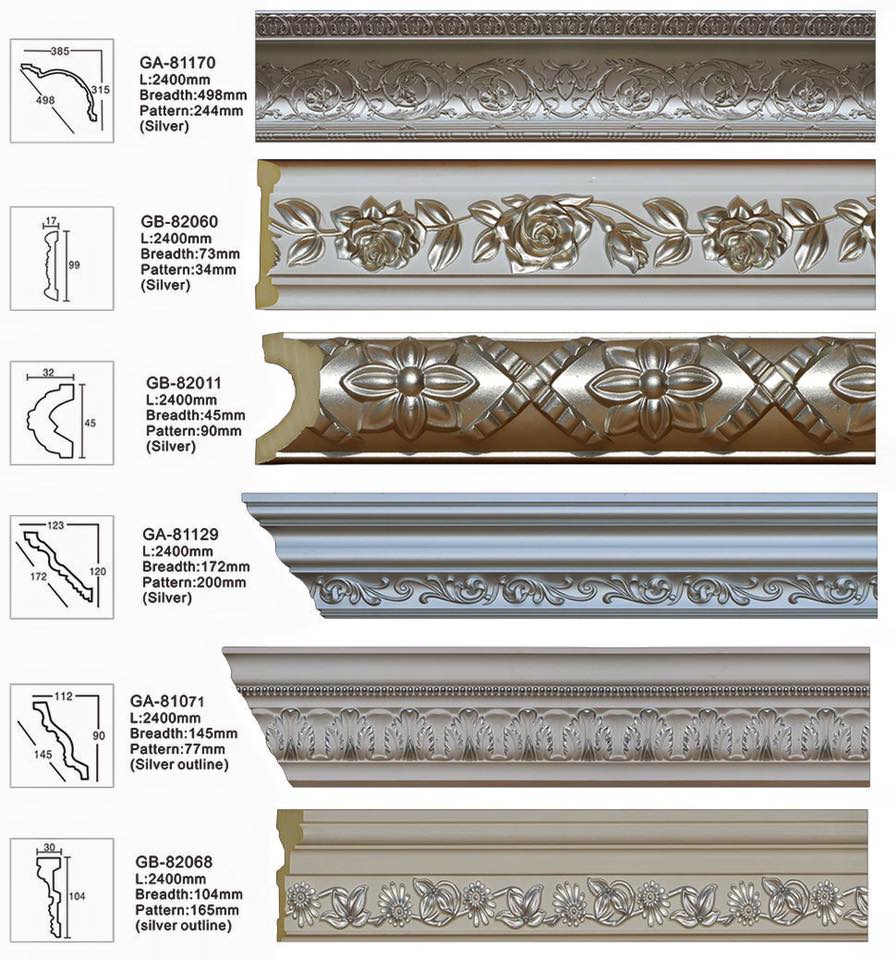

PU crown molding refer to lines made of PU synthetic materials. PU is the abbreviation of Polyurethane, and the Chinese name is

polyurethane for short. It is made of hard pu foam. This kind of rigid pu foam is mixed with two components at a high speed in the

pouring machine, and then enters the mold to form a hard skin. At the same time, it adopts fluorine-free formula and is not

chemically controversial. It is an environmentally friendly decorative product in the new century. Simply modify the formula to

obtain different physical properties such as density, elasticity, and rigidity.

PU line characteristics:

1. Moth-resistant, moisture-proof, mildew-proof, acid and alkali resistant, will not be cracked or deformed by weather changes, can be washed with water, and has a long service life.

2. Flame-retardant, non-spontaneous, non-combustible, and can be automatically extinguished when leaving the fire source.

3. Light weight, good hardness, good elasticity and toughness, and easy construction. It can be sawed, planed and nailed, and can be bent into various arc shapes at will. The time spent in construction is less than that of normal plaster and wood.

4. Diversity. Generally white is the standard. You can mix colors at will on the basis of white. It can also be used for special effects such as pasting gold, tracing gold, washing white, color makeup, antique silver, and bronze.

5. The surface pattern is clear and lifelike, and the three-dimensional effect is obvious.

6. It is light in weight, has a long service life, and is not easily deformed. The surface can be finished with latex paint or paint.