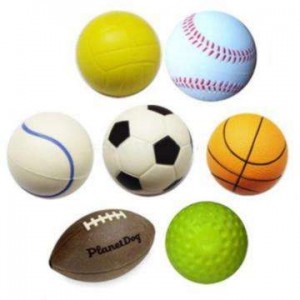

Polyurethane Cute Stress Plastic Toy Balls Mold PU Stress Toy Mold

1. Light weight: good resilience and tenacity, light and hard,.

2. Fire-proof: reach the standard of no combustion.

3. Water-proof: no moisture absorbing, water permeation and mildew arising.

4. Anti-erosion: resist acid and alkali

5. Environment protection: using polyester as raw material to avoid lumbering

6. Easy to clean

7. OEM serviece: We have employed R&D center for research, advanced production line, professional engineers and workers,service for you.Also we have successfully developed a design partnership with our OEM clients. Because of the unique high load capacity,high elasticity, wear and tear resistance of our casters and wheels, we are widely chosen by many customers in Middle East, European, South Asia, South America, ect.

|

Mold Type

|

Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc

|

|

Design software

|

UG, ProE, Auto CAD, Solidworks, etc.

|

|

Main services

|

Prototypes, Mold design, Mold making, Mold tesing,

low volume/high volume plastic production |

|

Certificate

|

ISO 9001:2008

|

|

Steel material

|

718H,P20,NAK80,S316H,SKD61, etc.

|

|

Production Raw material

|

PP,PU,ABS,PE,PC,POM,PVC etc

|

|

Mold base

|

HASCO ,DME ,LKM,JLS standard

|

|

Mold runner

|

Cold runner, hot runner

|

|

Mold hot runner

|

DME, HASCO, YUDO,etc

|

|

Mold cold runner

|

point way, side way, follow way, direct gate way,etc.

|

|

Mold strandard parts

|

DME, HASCO, etc.

|

|

mold life

|

>300,000 shots

|

|

Mold hot treatment

|

quencher, nitridation, tempering,etc.

|

|

Mold cooling system

|

water cooling or Beryllium bronze cooling, etc.

|

|

Mold surface

|

EDM, texture, high gloss polishing

|

|

Hardness of the steel

|

20~60 HRC

|

|

Equipments

|

High speed CNC, standard CNC, EDM, Wire cutting, Grinder,

Lathe, Milling machine, plastic injection machine

|

|

Lead time

|

25~30 days

|

|

Month Production

|

50 sets/month

|

|

Mold Packing

|

standard exporting Wooden case

|

Write your message here and send it to us