Polyurethane Low Pressure Foaming Machine Integral Skin Foam Making Machine

Characteristics and main uses of polyurethane

Since the groups contained in the polyurethane macromolecules are all strongly polar groups, and the macromolecules also contain polyether or polyester flexible segments, the polyurethane has the following

Feature

①High mechanical strength and oxidation stability;

② Has high flexibility and resilience;

③It has excellent oil resistance, solvent resistance, water resistance and fire resistance.

Because of its many properties, polyurethane has a wide range of uses.Polyurethane is mainly used as polyurethane synthetic leather, polyurethane foam, polyurethane coating, polyurethane adhesive, polyurethane rubber (elastomer) and polyurethane fiber. In addition, polyurethane is also used in civil engineering, site drilling, mining and petroleum engineering to block water and stabilize buildings or roadbeds; as a paving material, it is used for running tracks of sports fields, indoor floors of buildings, etc.

Low pressure foaming machine function

1. Polyurethane foaming machine has the characteristics of economic benefits, convenient operation and maintenance, etc., and can be customized according to customer requirements.

2. Adopt plc touch screen and man-machine interface operation panel, which is easy to use, and the operation of the machine is clear at a glance. The mixing head has low noise, is sturdy and durable, and the imported pump m威而鋼

easures accurately. Sandwich type barrel, good constant temperature effect.

3. Suitable for the production of polyurethane pillows, steering wheels, bumpers, self-made leather, high rebound, slow rebound, toys, fitness equipment, thermal insulation, bicycle seat cushions,

Automobile and motorcycle seat cushions, rigid foam, refrigerator plates, medical equipment, elastomers, shoe soles, etc.

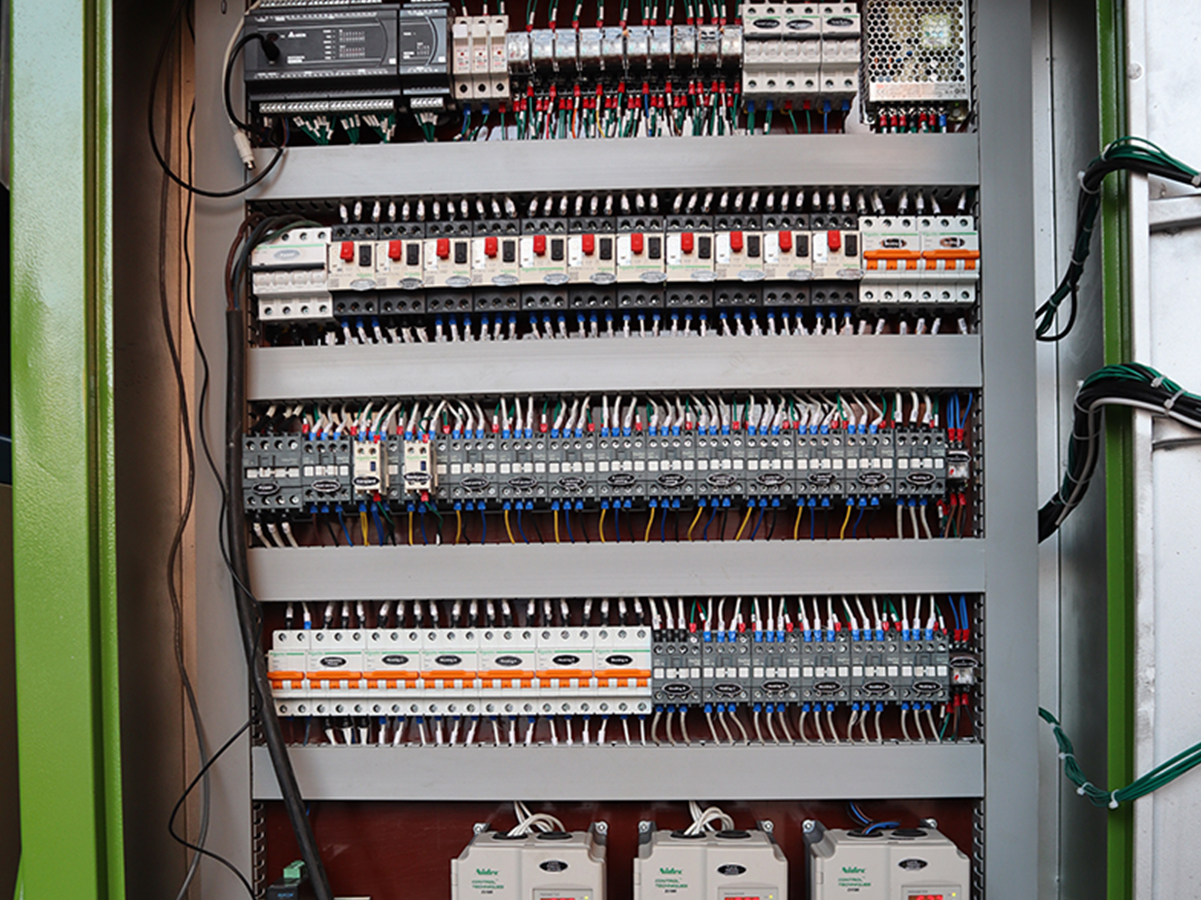

PLC Control System:Excellent quality, easy maintenance, convenient and flexible, stable operation, low failure rate.

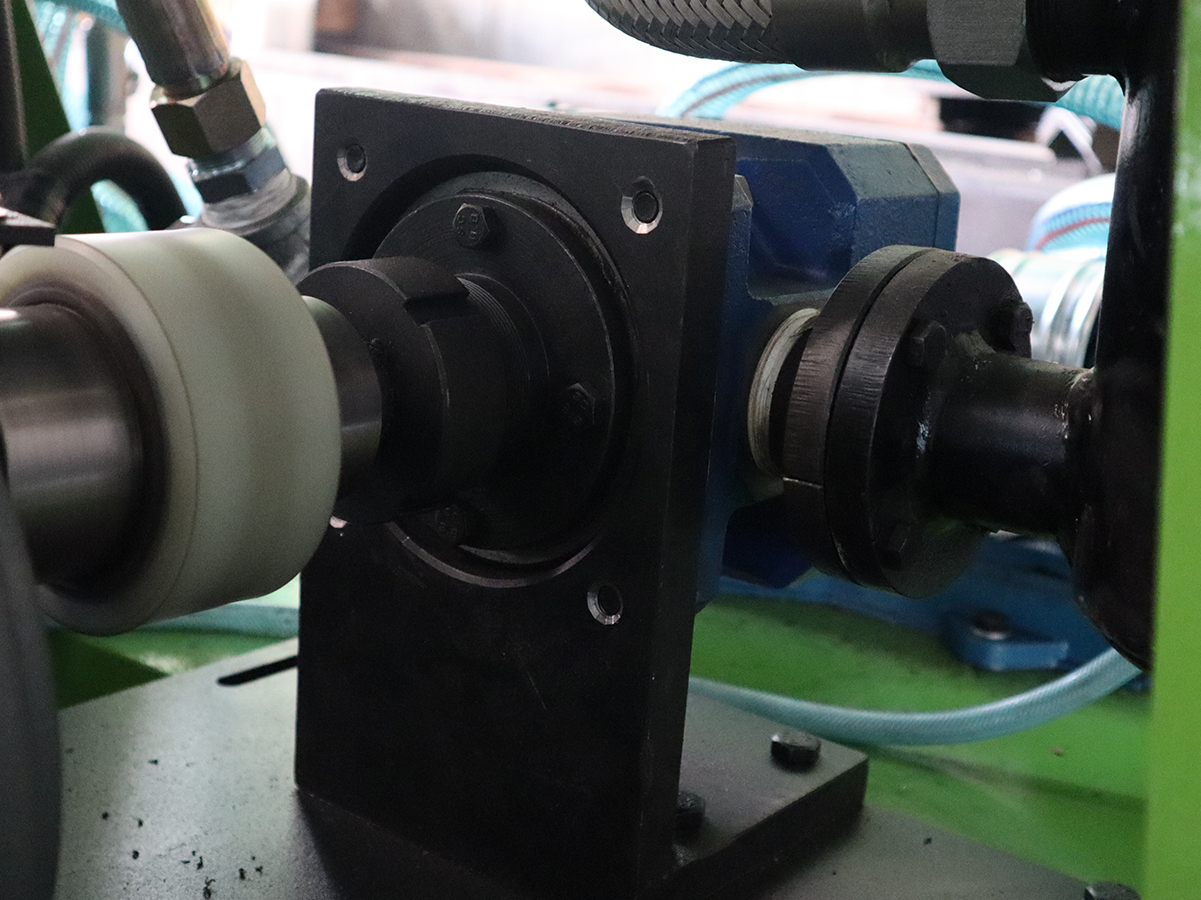

Brand Metering Pump:Accurate measurement, low failure rate and stable operation.

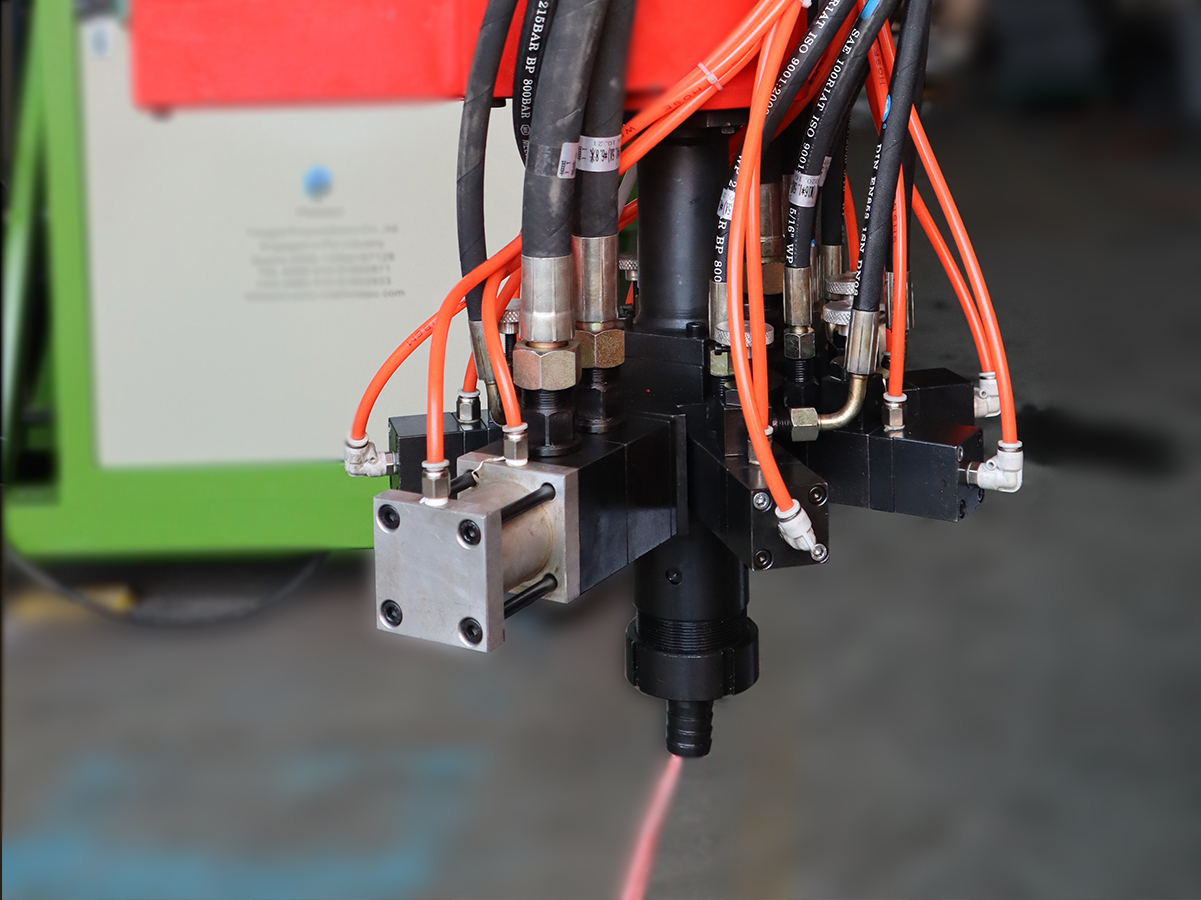

Mixing Head:Needle valve (ball valve) control, accurate pouring rhythm, full mixing and good foaming effect.

Stirring Motor:It is suitable for continuous operation with fast and stable speed, high efficiency, low noise and small vibration.

|

Item |

Technical parameter |

|

Foam application |

Integral Skin Foam Seat |

|

Raw material viscosity(22℃) |

POL ~3000CPS ISO ~1000MPas |

|

Injection flow rate |

26-104g/s |

|

Mixing ratio range |

100:28~48 |

|

Mixing head |

2800-5000rpm, forced dynamic mixing |

|

Tank Volume |

120L |

|

Input power |

Three-phase five-wire 380V 50HZ |

|

Rated power |

About 9KW |

|

Swing arm |

Rotatable 90°swing arm, 2.3m (length customizable) |

|

Volume |

4100(L)*1300(W)*2300(H)mm, swing arm included |

|

Color( customizable) |

Cream-colored/orange/deep sea blue |

|

Weight |

About 1000Kg |

PU self-skinning is a kind of foam plastic. It adopts the synthesis reaction of polyurethane two-component material. It is widely used in many fields such as steering wheel, instrument panel, public row chair, dining chair, airport chair, hospital chair, laboratory chair and so on.