Polyurethane High Pressure Foaming Machine For Table Edge

1. The mixing head is light and dexterous, the structure is special and durable, the material is discharged synchronously, the stirring is uniform, the nozzle will never be blocked, and the rotary valve is used for precision research and injection.

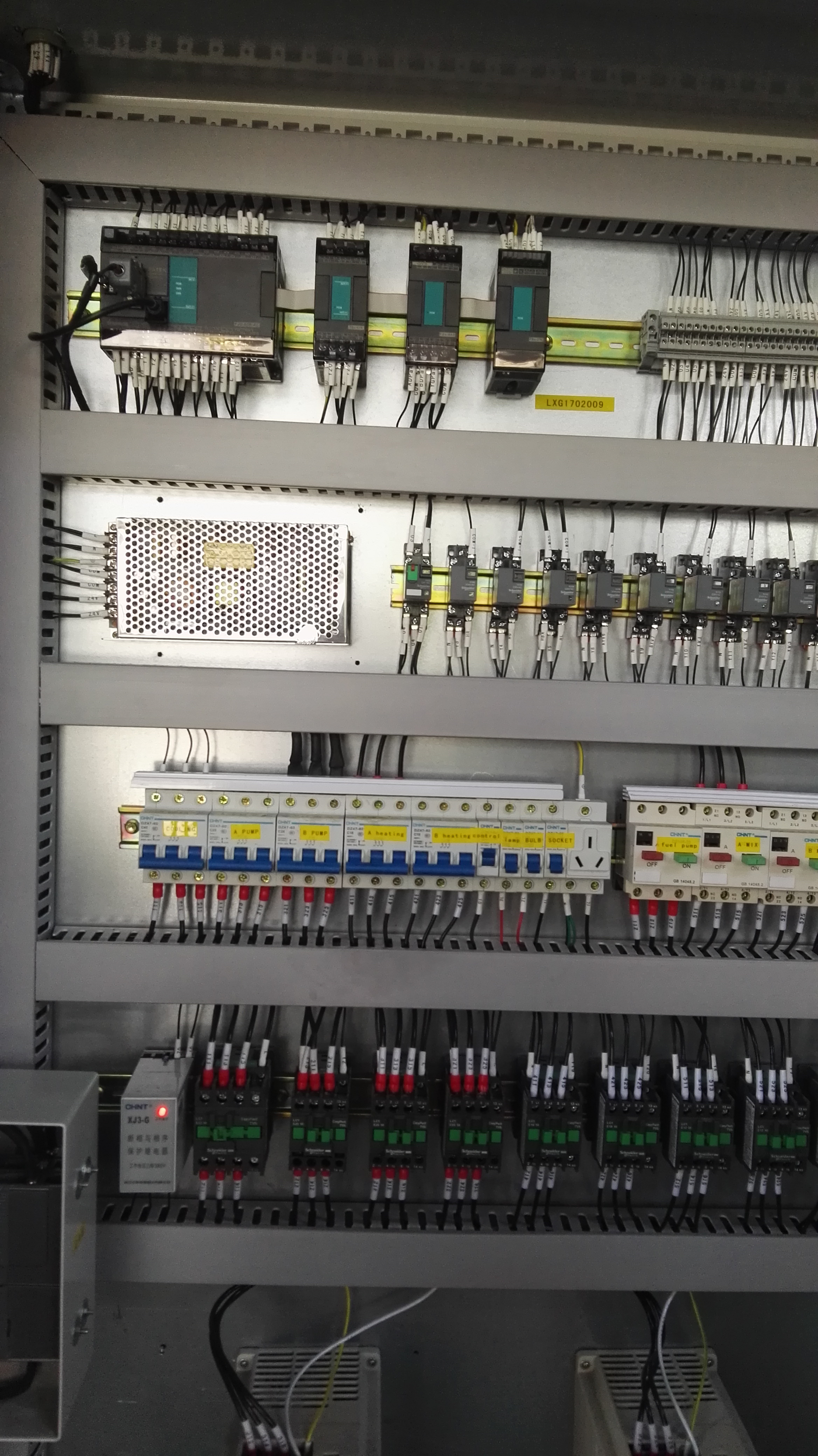

2. Microcomputer system control, with humanized automatic cleaning function, high timing accuracy.

3. The meter犀利士

ing system adopts a high-precision metering pump, which has high metering accuracy and is durable.

4. The three-layer structure of the material tank, the inner tank is made of stainless steel

|

Item |

Technical parameter |

|

Foam application |

Rigid foam |

|

raw material viscosity(22℃) |

~3000CPS ISO ~1000MPas |

|

Injection output |

80~375g/s |

|

Mixing ratio range |

100:50~150 |

|

mixing head |

2800-5000rpm, forced dynamic mixing |

|

Tank volume |

120L |

|

metering pump |

A pump: GPA3-25 Type B Pump: GPA3-25 Type |

|

input power |

three-phase five-wire 380V 50HZ |

|

Rated power |

About 12KW |

Good flexibility, even if it is sealed on a small radius sheet, it will not break. Its edge seal gap is so small that the gap is barely visible. Edge seals and cabinets are specially sealed.

The surface has an abrasion-resistant layer that has good abrasion resistance, is not easy to fade, is resistant to cleaning agents, and is especially easy to care for when dirty.

Furniture decorative strips have good dimensional stability and will not shrink or expand excessively due to large temperature differences.

The raw materials of furniture decorative strips contain additives, the color is stable, and will not change color under ultraviolet radiation. After using the edge strip for a while, the trimmed surface will glow without sticking to dust or blackening.