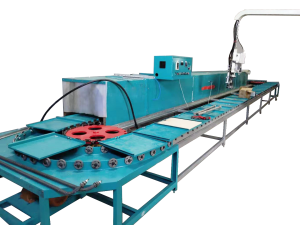

Fully Auto Continuous PU Polyurethane Foam Sponge Making Machine

This continuous foaming machine skillfully combines overflow tank foaming and pouring foaming. It breaks through the traditional foaming from bottom to top, gathers the advantages of domestic and foreign foaming machinery, and combines the market demand. A new generation of horizontal continuous foaming machine developed.

Our continuous block molding machine is mainly suitable for the production of soft polyurethane foam spongewith a density range of 8-80kg/m3. It adopts a man-machine interface control system with a high degree of automation and a more flexible mastery. The formula can be adjusted or changed, and can be controlled remotely through the Internet, making the control of production costs more scientific and intuitive.

| Foaming group | 13 Groups |

| Foaming type | Sprayer/ Trough |

| Foaming width | 1150-2250mm |

| Foaming heigh | 1300mm |

| Foaming density | 8-80kg/m3 |

| Foaming speed | 2000- 8000mm/min |

| Output | 200- 3501L/min |

| Mixing head power | 37kw |

| Total power | 130kw |

| Oven length | 1800mm |

| Machine external size | L35000 x W4500 x H4200mm |

It can produce a variety of ideal furniture cotton, shoe material cotton, bust cotton, electronic cotton, as well as various foams suitable for packaging, clothing and automobile industries.

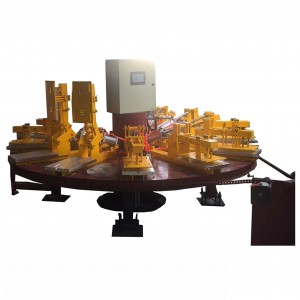

PLC Control Continuous Polyurethane Foam Machine PU Foam Sponge Making Machine For Sofa or Mattress