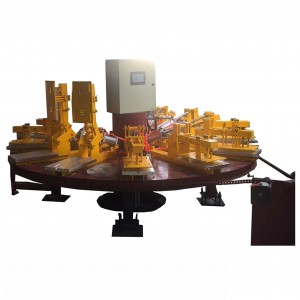

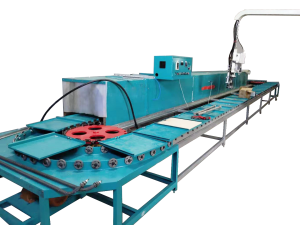

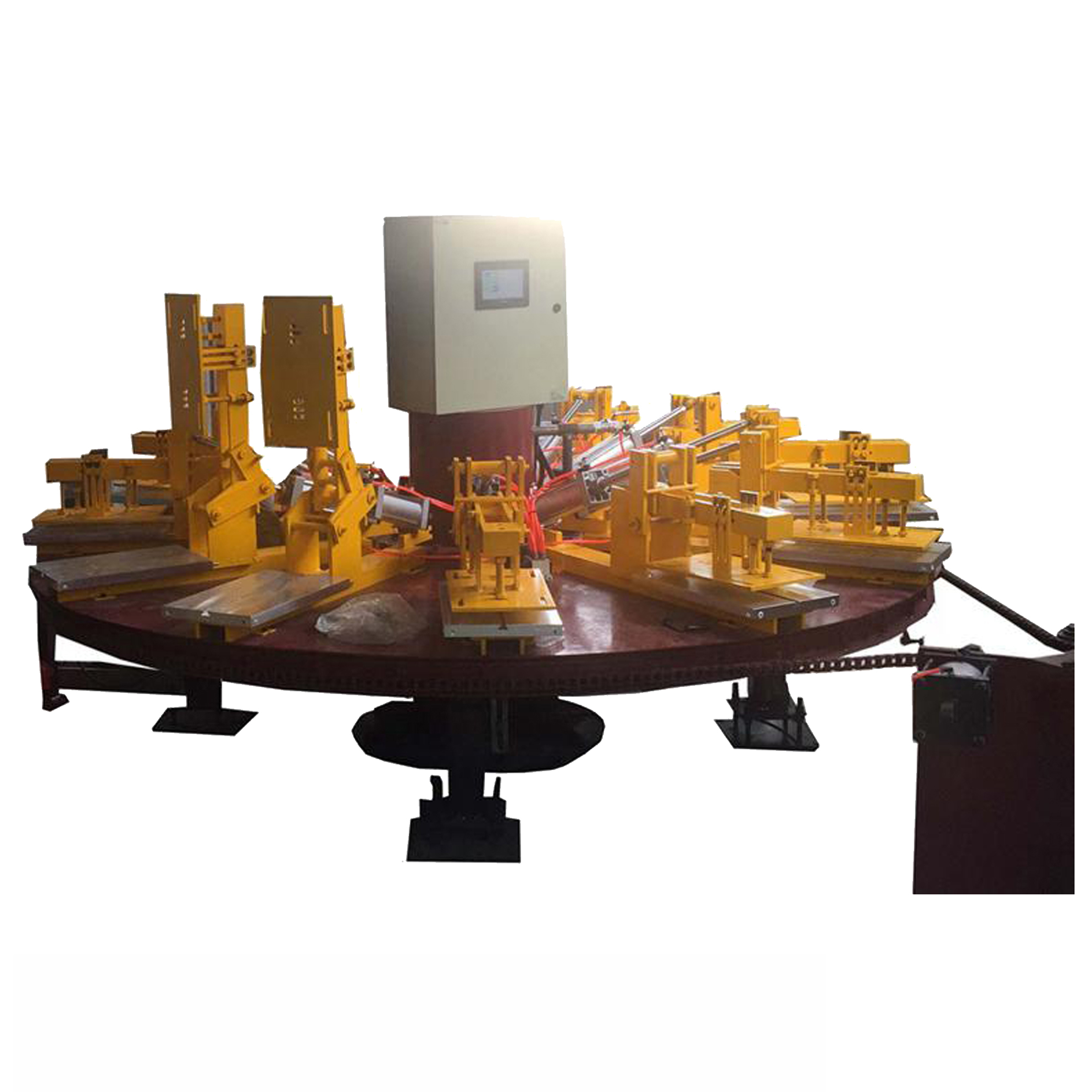

Polyurethane Foam Insole Making Machine PU Shoe Pad Production Line

The automatic insole and sole production line is an ideal equipment based on our company’s independent research and development, which can save labor cost, improve production efficiency and automatic degree, also possess the characteristics of stable performance, accurate metering, high precision positioning, automatic position identifying.

Ring production line parameters:

The length of the ring line is 19000, the power of the transmission motor is 3kw/GP, and the frequency conversion speed regulation;

60 workstations;

The length of the drying tunnel is 14000, the heating power is 28kw, and the internal machine is 7X1.5kw;

Open and close the mold using Xinjie servo motor 1.5kw, reducer PF-115-32;

Adopt Panasonic PLC control, 10-inch touch screen;