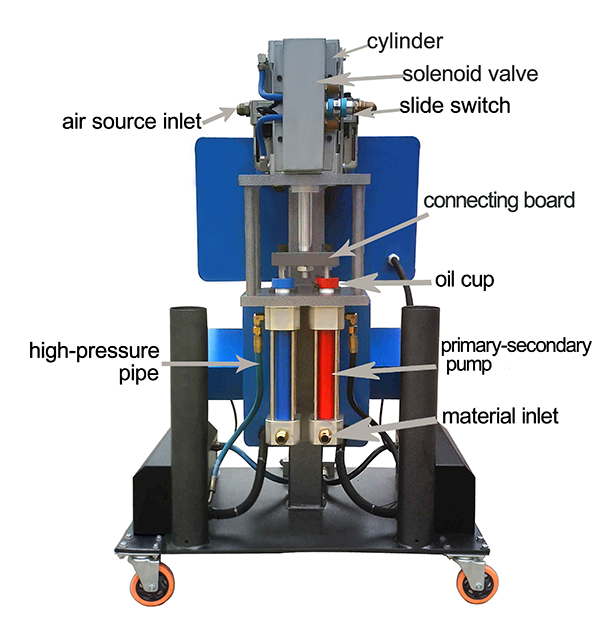

Polyurethane Insulation Foam JYYJ-3H Spray Machine

JYYJ-3H This equipment can be used for various construction environment with spraying a variety of two-component materials spray(optional) like polyurethane foaming materials, etc.

Features

1. Stable cylinder supercharged unit, easily providing adequate working pressure;

2. Small volume, light weight, low failure rate, simple operation, easy mobility;

3. Adopting the most advanced ventilation method, guarantee equipment working stability to the maximum;

4. Minimizing spraying congestion with 4-layers-feedstock device;

5. Multi-leakage protection system to protect the safety of the operator;

6. Equipped with emergency switch system, help operator deal with emergencies rapidly;

7. Reliable & powerful 220V heating system enables rapid warming of raw materials to the best state, making sure it works great in cold condition;

8. Humanized design with equipment operation panel, super easy to get the hang of it;

9. Feed pump adopts big change ratio method, it can easily feed raw materials high viscosity even in winter.

10. The latest spraying gun has great features like small volume, light weight, low failure rate, etc;

Raw material outlet: Outlet of Iso and polyol materials and are connected with Iso and polyol material pipes;

Main power: Power switch to turn on and off of the equipment

Iso/polyol material filter: filtering impurities of Iso and polyol material in the equipment;

Heating tube: heating Iso and polyol materials and is controlled by Iso/polyol material temp. control

Power Input : AC 220V 60HZ;

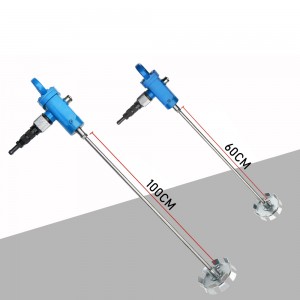

Primary-Secondary pumping system: booster pump for A, B material;

Raw material inlet : Connecting to feeding pump outlet

Solenoid valve(electromagnetic valve): Controlling reciprocating motions of cylinder

|

Raw material |

polyurethane |

|

Features |

without metering control |

|

POWER SOURCE |

3-phase 4-wires 380V 50HZ |

|

HEATING POWER (KW) |

9.5 |

|

AIR SOURCE (min) |

0.5~0.8Mpa≥0.9m3 |

|

OUTPUT(kg/min) |

2~12 |

|

MAXIMUM OUTPUT (Mpa) |

11 |

|

Matrial A:B= |

1;1 |

|

spray gun:(set) |

1 |

|

Feeding pump: |

2 |

|

Barrel connector: |

2 sets heating |

|

Heating pipe:(m) |

15-75 |

|

Spray gun connector:(m) |

2 |

|

Accessories box: |

1 |

|

Instruction book |

1 |

|

weight:(kg) |

109 |

|

packaging: |

wooden box |

|

package size(mm) |

910*890*1330 |

|

pneumatic driven |

√ |

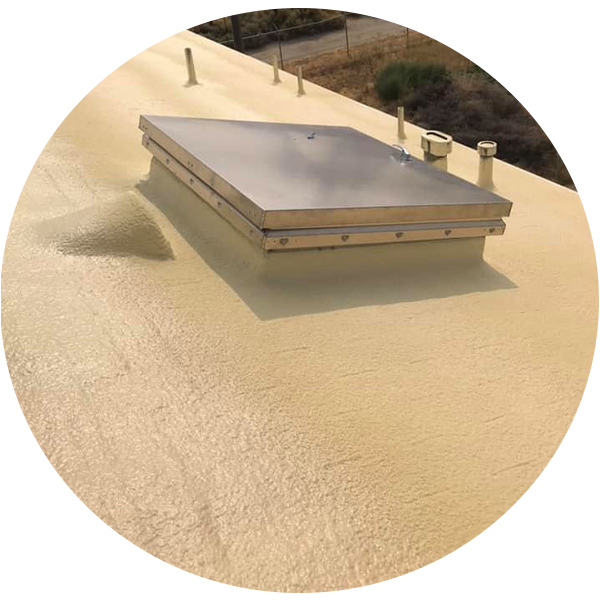

The spray foaming machine is widely used in embankment waterproof, pipeline corrosion, auxiliary cofferdam, tanks, pipe coating, cement layer protection, wastewater disposal, roofing, basement waterproofing, industrial maintenance, wear-resistant linings, cold storage insulation, wall insulation and so on.