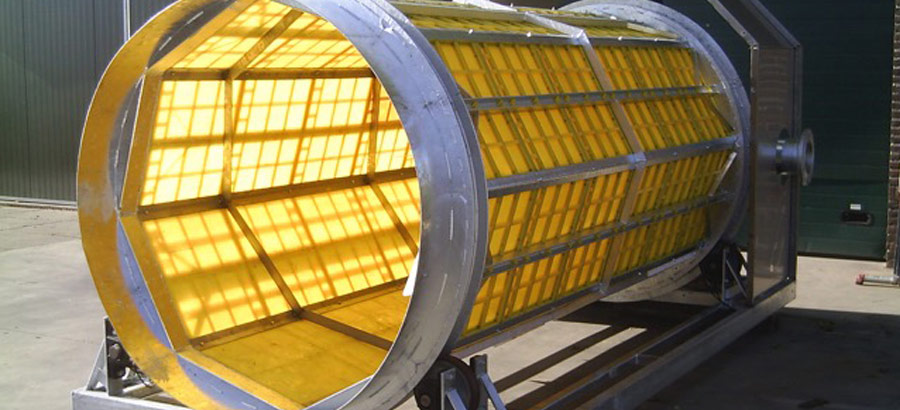

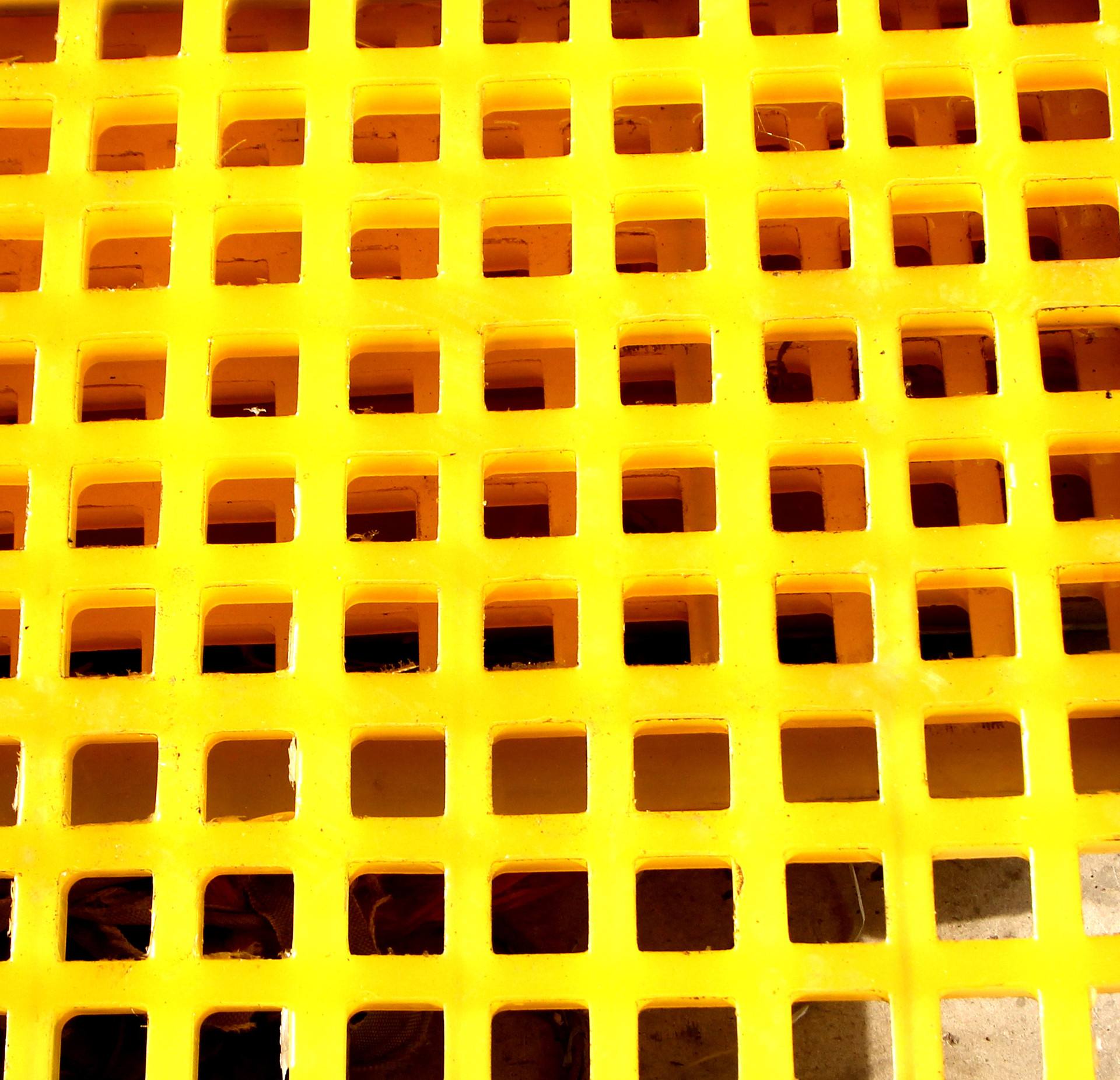

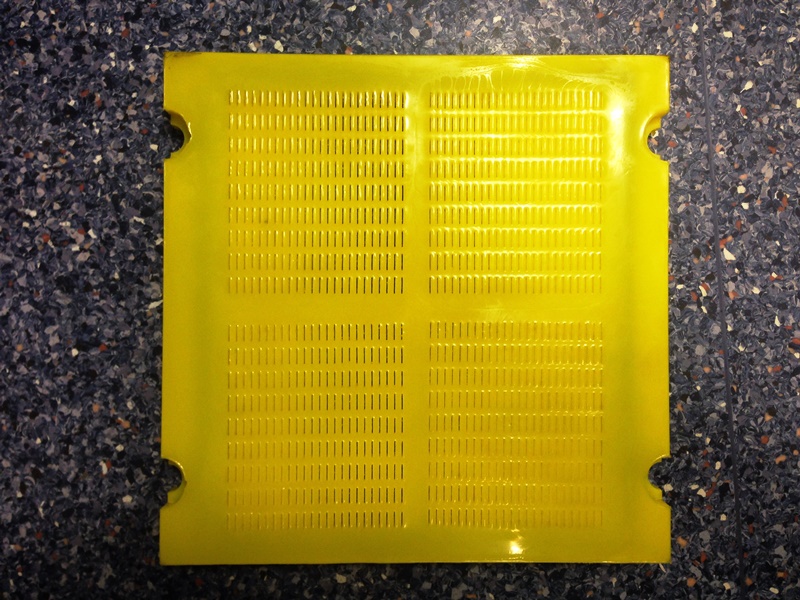

PU Casting Machine For Polyurethane Mine Screen PU Elastomer Machine

1. The equipment adopts a high-performance PLC control system and a 10.2-inch touch screen as the upper display interface. Because the PLC has a unique power-off hold function, abnormal automatic diagnosis function and forget cleaning function. Using special storage technology, the relevant data of settings and records can be permanently saved, eliminating the phenomenon of data loss caused by long-term power failure.

2. The equipment independently develops a comprehensive automatic control program according to the technological process of the product, with stable performance (no crash, program confusion, program loss, etc.) and high automation performance. The equipment program control system can also be customized according to the customer’s product process requirements, and the main components of the control system are guaranteed for two years

3. The machine head is equipped with an anti-reverse device, which solves the problem of pouring material during pouring.

4. The prepolymer material tank adopts a special kettle with precise mechanical seal to solve the problem of long-term storage deterioration and vacuum.

5. The MOC component heating system adopts secondary filtration to prevent the carbonization of the heat transfer oil and solve the problem of pipeline blockage.

Buffer tank Buffer tank used for vacuum pump to filtering and pump Vacuum pressure accumulator. Vacuum pump draws air in the tank through the buffer tank, lead the raw material air reduction and achieve less bubble in the final products.  Pour head Adopting high speed cutting propeller V TYPE mixing head (drive mode: V belt), ensure even mixing within the required pouring amount and mixing ratio range. Motor speed increased through a synchronous wheel speed, making the mixing head rotate with high speed in mixing cavity. A, B solution are switched to casting state by their respective conversion valve, come into the mixing champer through orifice. When the mixing head was at high speed rotation, it should be equipped with reliable sealing device to avoid pouring material and ensure the normal operation of the bearing.

Pour head Adopting high speed cutting propeller V TYPE mixing head (drive mode: V belt), ensure even mixing within the required pouring amount and mixing ratio range. Motor speed increased through a synchronous wheel speed, making the mixing head rotate with high speed in mixing cavity. A, B solution are switched to casting state by their respective conversion valve, come into the mixing champer through orifice. When the mixing head was at high speed rotation, it should be equipped with reliable sealing device to avoid pouring material and ensure the normal operation of the bearing.

| Item | Technical Parameter |

| Injection Pressure | 0.1-0.6Mpa |

| Injection flow rate | 50-130g/s 3-8Kg/min |

| Mixing ratio range | 100:6-18(adjustable) |

| Injection time | 0.5~99.99S (correct to 0.01S) |

| Temperature control error | ±2℃ |

| Repeated injection precision | ±1% |

| Mixing head | Around 5000rpm (4600~6200rpm,adjustable),forced dynamic mixing |

| Tank volume | 220L/30L |

| A maximum working temperature | 70~110℃ |

| B maximum working temperature | 110~130℃ |

| Cleaning tank | 20L 304# stainless steel |

| Compressed air requirement | dry, oil free P:0.6-0.8MPa Q:600L/min(Customer-owned) |

| Vacuum requirement | P:6X10-2Pa(6 BAR) speed of exhaust:15L/S |

| Temperature control system | Heating: 18~24KW |

| Input power | three-phrase five-wire,380V 50HZ |

| Heating power | TANK A1/A2: 4.6KW TANK B: 7.2KW |