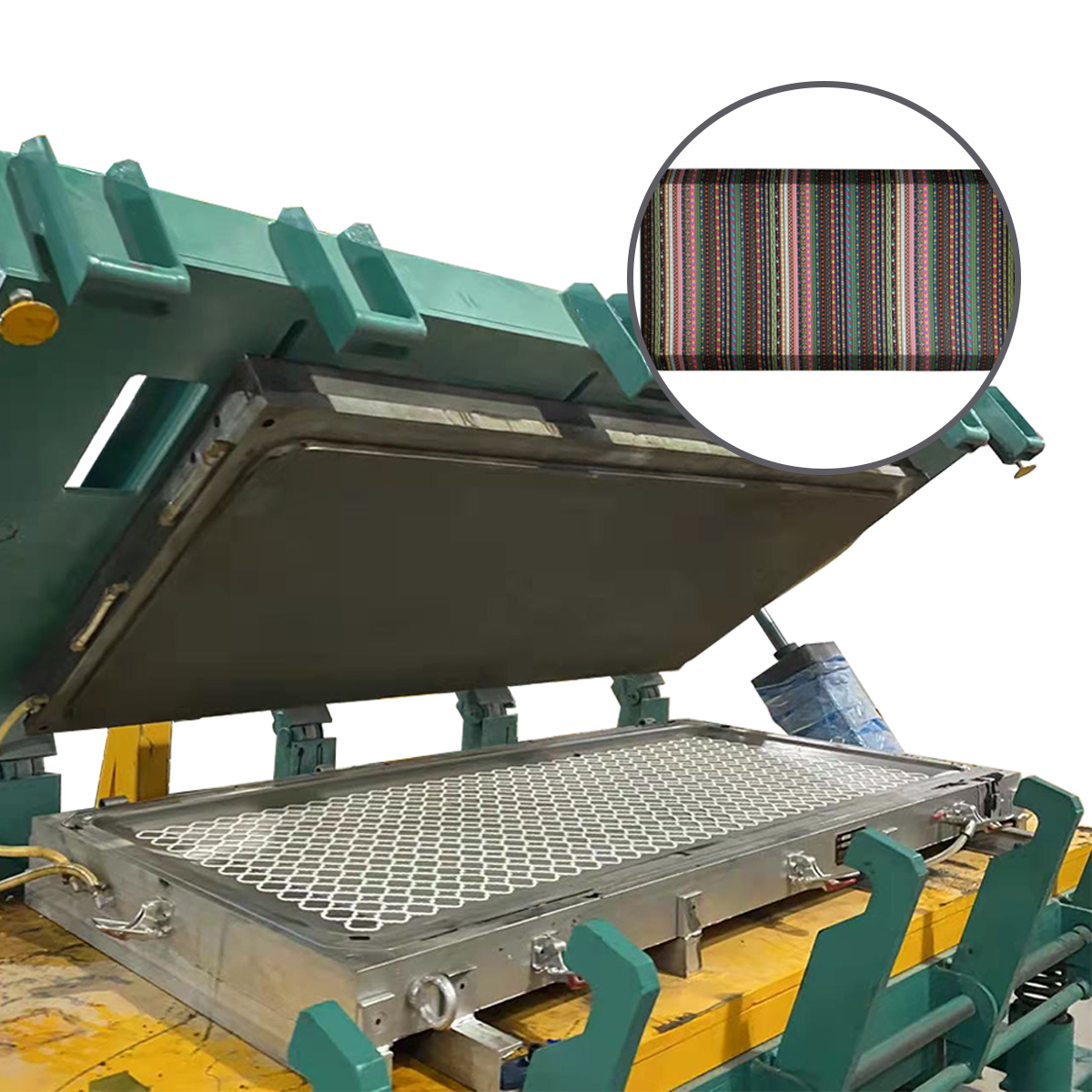

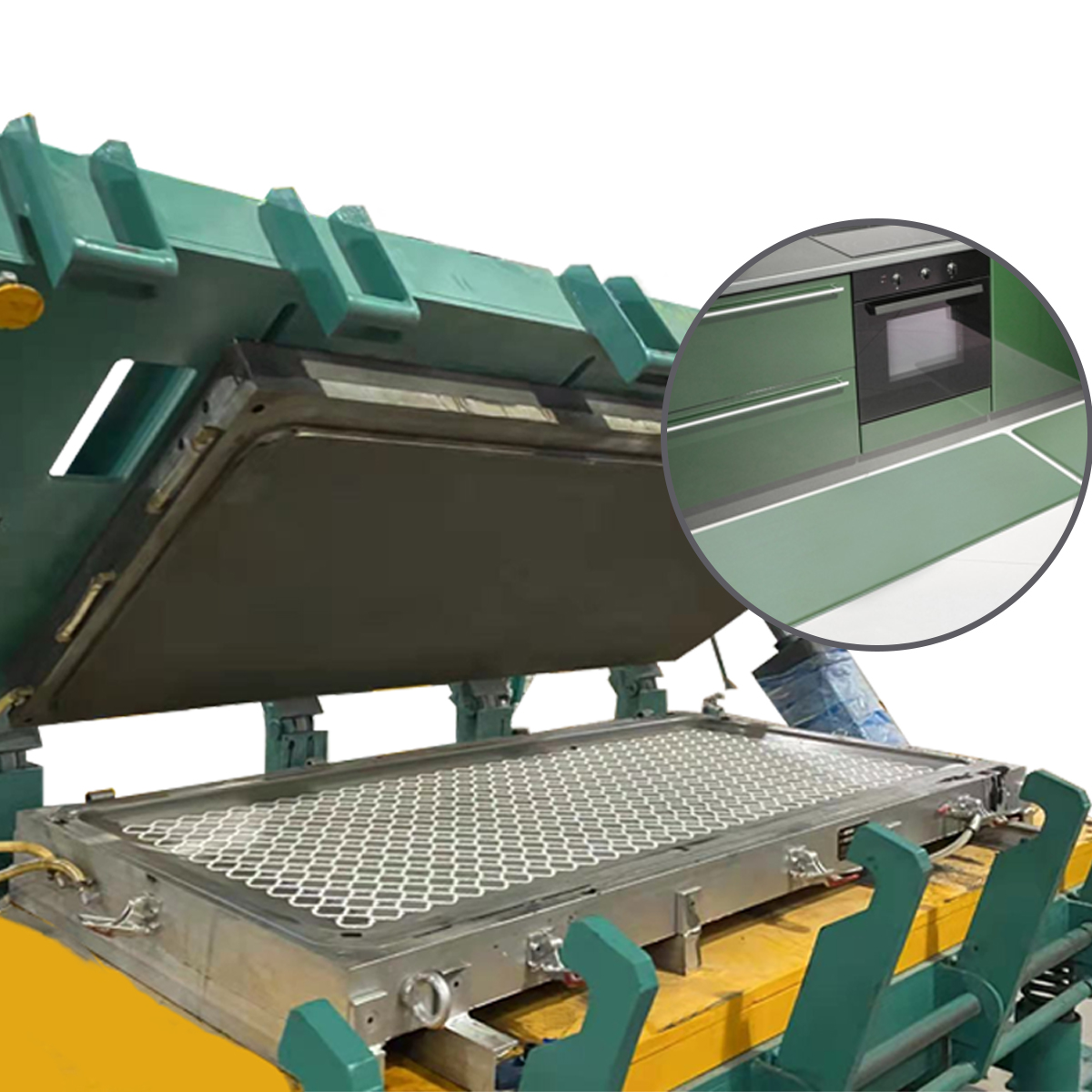

Polyurethane Foam Anti-fatigue Mat Mold Stamping Mat Mold Memory Foam Prayer Mat Making Mould

Our moulds are used to produce floor mats of various styles and sizes. As long as you provide the product design drawings you need, we can help you produce the floor mat molds you need according to your drawings.

Floor mat molds are generally made of steel, which is sturdy and durable, and can withstand hundreds of thousands of repeated pouring. We have professional engineers to provide drawing design service, or if you have your own design, you can also provide it to us, and we will make mold production according to your drawings.

|

Mold Type

|

Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, stamping, die casting mold, etc

|

|

Design software

|

UG, ProE, Auto CAD, Solidworks, etc.

|

|

Main services

|

Prototypes, Mold design, Mold making, Mold tesing,

low volume/high volume plastic production |

|

Certificate

|

ISO 9001:2008

|

|

Steel material

|

718H,P20,NAK80,S316H,SKD61, etc.

|

|

Production Raw material

|

PP,PU,ABS,PE,PC,POM,PVC etc

|

|

Mold base

|

HASCO ,DME ,LKM,JLS standard

|

|

Mold runner

|

Cold runner, hot runner

|

|

Mold hot runner

|

DME, HASCO, YUDO,etc

|

|

Mold cold runner

|

point way, side way, follow way, direct gate way,etc.

|

|

Mold strandard parts

|

DME, HASCO, etc.

|

|

mold life

|

>300,000 shots

|

|

Mold hot treatment

|

quencher, nitridation, tempering,etc.

|

|

Mold cooling system

|

water cooling or Beryllium bronze cooling, etc.

|

|

Mold surface

|

EDM, texture, high gloss polishing

|

|

Hardness of the steel

|

20~60 HRC

|

|

Equipments

|

High speed CNC, standard CNC, EDM, Wire cutting, Grinder,Lathe, Milling machine, plastic injection machine

|

|

Lead time

|

25~30 days

|

|

Month Production

|

50 sets/month

|

|

Mold Packing

|

standard exporting Wooden case

|

Anti-slip and anti-fatigue mats, high-performance anti-fatigue, relieve the pressure of blood circulation on the feet, and improve the health index and safety factor of employees. Resistant to acid and alkali solvents. It is convenient to clean, easy to move, and does not affect the normal working environment.