Automotive Air Filters Gasket Casting Machine

Featurer

The machine has high degree of automation, reliable performance, convenient operation and simple maintenance. It can be cast into various shapes of polyurethane sealing strips on a plane or in a groove as required. The surface is thin self-skinning, smooth and highly elastic. Equipped with imported mechanical movement trajectory control system, it can run fully automatically according to the geometric shape required by the user. The advanced and reliable trajectory control system solves the problem of glue stacking at the corners or arcs of similar products at home and abroad.

Character

Raw material tank: Three-layer stainless steel structure with stirring and automatic constant temperature.

Metering Pump: It adopts low-speed high-precision and precise transmission and display device.

Mixing Head: Automatic three-position transformation (pouring, reflow, cleaning) will not lead and lag. After the work is completed, the pneumatic shift program-controlled automatic cleaning.

Worktable: The mold is positioned on the automatically controlled universal worktable, which is controlled by imported mechanical movement and servo motor, so as to ensure balanced movement, no noise, high precision and long service life.

Control System: Digital display and automatic control of temperature, pressure, number of revolutions and pouring amount. Using man-machine dialogue interface, using advanced and reliable CNC2000 programming, programming is simple and clear, and real-time verification, simulation, monitoring.

Raw Material Tank:

The volume of the material tank is 30-120L optional, the inner tank is 304 stainless steel, the outer layer is Q235-A board, the interlayer is a circulating water jacket, the outer wall of the Q235-A board is attached with a layer of EVA insulation material, and the top of the material tank is installed with a 0.55KW cycloid Reducer, speed ratio 1:59, in order to ensure full stirring and constant temperature of raw materials.

Metering Pump:

It adopts low-speed high-precision and precise transmission and display device.

Mixing Head:

Automatic three-position transformation (pouring, reflow, cleaning) will not lead and lag. After the work is completed, the pneumatic shift program-controlled automatic cleaning.

Worktable:

The mold is positioned on the automatically controlled universal worktable, which is controlled by imported mechanical movement and servo motor, so as to ensure balanced movement, no noise, high precision and long service life.

Control System:

Digital display and automatic control of temperature, pressure, number of revolutions and pouring amount. Using man-machine dialogue interface, using advanced and reliable CNC2000 programming, programming is simple and clear, and real-time verification, simulation, monitoring.

Metering system:

The metering pump is driven by a variable frequency speed regulating motor, which has a wide adjustment range and a stable speed. A and B component metering pump adopts domestic high-precision external meshing gear pump, with accurate metering, low noise, wear resistance, and measurement error less than 0.5%.

Meter

Including temperature, pressure and rotation speed, by controlling the constant temperature, it is ensured that the output of the raw material does not affect the rotation speed and pressure with the change of viscosity. Similarly, the blockage of the pipeline can be seen through the change of rotation speed and pressure.

Cleaning System

After the pouring is completed, the cylinder with a stroke of 600mm pushes the mixing head to retract to the cleaning position, and the computer automatically controls continuous actions such as air flushing, liquid washing, and drying. The cleaning tank volume is 20L, and the solenoid valve adopts AirTAC.

| Max Size of Squareness (mm) | 700*700 |

| Max Size of roundness (mm) | Φ650 |

| Dimension(mm) | 1380*2100*2300 |

| Weight(kg) | About 1200kg |

| Total Power (kw) | 9kw |

| Power Voltage, Frequency | 380V 50HZ |

| Designed Mixture Ratio | A:B=100:25-35 |

| Moving Speed Of Worebench | 2.24m/min |

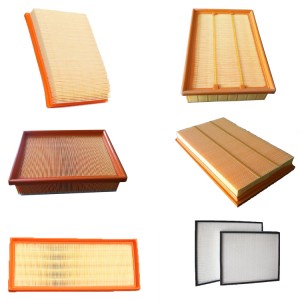

It can used in the production of automotive air filters, industrial filter polyurethane gaskets and electrical cabinet sealing strips, etc.